Response Surface Optimization of Ca2+ Treatment for Texture Improvement on Kelp Products

-

摘要: 为解决海带热处理过程易软化而导致品质劣变的技术难题,以盐渍海带为原料,运用钙盐漂烫技术,以质构综合指数为指标,研究CaCl2质量浓度、漂烫温度及漂烫时间等因素对钙盐漂烫保质效果的影响,采用Box-Behnken响应面试验设计进行参数优化。结果表明:CaCl2质量浓度对海带钙盐漂烫品质的影响呈先上升后趋于平缓的趋势,反应温度和时间对海带钙盐漂烫品质的影响均呈先增加后减少的趋势,差异均达显著水平(P < 0.05)。影响质构品质的因素依次为:漂烫时间 > 漂烫温度 > CaCl2质量浓度。漂烫温度与时间对质构综合指数影响的交互作用达显著水平(P < 0.05)。参数寻优为:漂烫温度88.0℃,CaCl2质量浓度1.54 g·L-1,漂烫时间4 min 40 s漂烫时间4.77 min,CaCl2质量浓度1.54 g·L-1,漂烫温度87.8℃。在此条件下,Ca2+处理的海带组织紧密,质地脆嫩,质构综合指数达86.11±0.02。Abstract: To overcome the texture softening of thermally processed kelp products, salted kelp was treated with CaCl2 solution by a single factor test and further optimized by a response surface experiment. The conditions that affected the textual quality were found to be in the order of:blanching time>blanching temperature > CaCl2concentration. The temperature and time applied in blanching had significant effects on texture of the processed kelp (P < 0.05). Kelps blanched in a CaCl2 1.54 g·L-1 water solution at 88.0℃ for 4 min and 40 s could yield a crispy and yet tender product with a high composite texture index of 86.11±0.02.

-

Keywords:

- kelp /

- texture quality /

- Ca2+ treatment /

- blanching /

- response surface methodology

-

海带Laminaria japonica是一种多年生大型海生藻类植物[1]。根据联合国粮农组织(FAO)的数据统计[2],我国海带产量居世界第一位,约占世界产量的50%。近年来,福建省通过项目扶持,新建了一大批海带养殖基地,产量逐年增加,2014年达263.82万t。海带中富含营养成分,其脂肪含量和热量低,纤维素含量高,具有减肥功效;此外,海带还具有抗癌、降三高、提高免疫力、预防便秘、延缓衰老等功效[3],符合现代人的饮食结构,成为当代食疗的最佳选择之一。海带成本比较低,加工品大都以传统的盐渍海带[4]、海带卷[5]、海带粉[6]、海带结[7]和海带丝[8]等一些初级产品形式为主,缺乏高附加值产品的开发,限制了海带市场前景。近几年也有学者对海带深加工技术进行研究,在加热、发酵等加工过程中,存在因藻体易软化而致品质劣变的问题,制约了其产业的发展[9]。

Ca2+因能与食品原料中的果胶、海藻胶等发生化学作用形成不溶性的钙盐,常用于食品的稳定和保脆处理[10]。海带中含有丰富的褐藻糖胶,与Ca2+等二价阳离子发生化学作用,可形成具有三维网络结构的水凝胶,使组织结构变紧密[11, 12]。因此,可通过Ca2+处理破解海带加工品质软化劣变问题,提高海带的质构品质。借助质构仪分析评价食品质构品质指标具有其客观性和可重复性的优点,但在运用质构指标评价食品质构品质的时候,单一的质构指标并不能全面有效地评价食品的品质,而使用多个指标评价又会出现信息的重叠,且各质构指标并不是越大越好,或者越小越好,评价起来存在一定的困难[13-15]。项目组前期研究结果表明[16],根据海带的各质构指标与感官得分存在二次函数关系,将质构指标参数转化为与感观感官得分呈正相关的质构指标指数,通过主成分分析与归一化处理,提出了质构综合指数评价方法,此法可客观评价海带综合品质。本试验以盐滞海带为原料,以质构综合指数为指标,在单因素试验的基础上,通过响应面分析得到其优化组合,研发海带钙盐漂烫保质技术,可破解海带热处理易软化而致品质劣变的技术难题,为海带的深加工开发利用提供质构品质控制的技术支持。

1. 材料与方法

1.1 材料与试剂

盐渍海带:新鲜海带用35%的食盐盐渍24 h后,于-20℃速冻保藏。由福建省红太阳精品有限公司提供。

氯化钙、食盐均为食品级。

1.2 仪器与设备

TA-XT Plus型质构仪,英国SMS公司;数显恒温水浴锅,常州国华电器有限公司。

1.3 试验方法

1.3.1 单因素试验

盐渍海带脱盐后,按料液比1: 3,以不同质量浓度的CaCl2溶液、在一定温度下漂烫一定时间,冷却、沥干之后切条,取海带中部[宽度(1±0.15)cm、厚度(1.90±0.10)mm]进行质构测定。设置不同的参数:温度参数为60、70、80、90、100℃,漂烫时间参数为0、2、4、6、8、10、12 min,CaCl2溶液的质量浓度参数为0、0.5、1.0、1.5、2.0、2.5 g·L-1;固定参数为漂烫时间4 min,CaCl2溶液的质量浓度1.5 g·L-1,漂烫温度70℃,以质构综合指数为指标进行单因素试验。

1.3.2 Box-Behnken响应面试验设计试验

在单因素试验的基础上,选择漂烫温度、CaCl2质量浓度、漂烫时间3个因素,以海带质构综合指数为指标进行响应面设计。试验因素及水平见表 1。

表 1 响应面试验设计因素与水平Table 1. Factors and levels of response surface experimental design因素 编码 水平 -1 0 1 漂烫温度/℃ X1 85 90 95 CaCl2质量浓度/(g·L-1) X2 1.0 1.5 2.0 漂烫时间/min X3 3 4 5 1.4 检测方法

1.4.1 质构特性测定

TPA测试参数:选用P/5R探头进行TPA模式的质构测定,测前速度=1.00 mm·s-1,测后速度=1.00 mm·s-1,测试速度=1.00 mm·s-1,触发力=5 g,下压距离为3 mm,两次压缩停留间隔时间=5 s,数据采集速率为400 p·s-1,每份样品平行测定9次,取平均值。

1.4.2 海带感官评价

采用层次分析法建立海带的评价域U={质地,色泽,气味,口味},设定各评价指标的模糊权向量A={0.50,0.10,0.10,0.30},设定评价等级V={很好,较好,一般,差},品评标准见表 2。选用M(-,+)算子建立模糊综合评价模型,各等级的轶标准见表 3,每个样品构成一个普通集合(论域):F={F1,F2,…,F19},Fi{i=1,2,…,19}。Fi表示i种海带样品,根据隶属度采用秩加权平均原则进行感官模糊综合评价。

表 2 感官评分标准Table 2. Criteria for sensory evaluation项目 很好 较好 一般 差 质地 藻体均匀,组织紧密,质地脆嫩 藻体均匀,组织紧密,质地较脆嫩 藻体不均匀,组织过紧密或松弛,质地略硬或略软 藻体不均匀,组织过紧密或松弛,质地过硬 色泽 均匀,表面有光泽,不暗淡 均匀,表面有光泽,光泽度略差 不均匀,色泽暗淡,光泽度略差 不均匀,色泽很暗淡,光泽度很差 气味 藻香味浓郁,无异味 藻香味明显,无异味 有轻微藻香味,有异味 藻香味不浓,异味严重 口味 无苦涩味,海带味正常 无苦涩味,海带味道略不正常 略有苦涩味,海带味道不正常 苦涩味明显,有异味 表 3 各等级的轶值Table 3. Proliferation valuesforproduct grading很好 较好 一般 差 分值 7~10 5~7 3~5 1~3 轶 8.5 6 4 2 1.4.3 质构综合指数

按王红丽建立的质构综合评价方法进行[16]。

(1) 指标转化:建立感观得分与某质构指标的函数关系,分析感观得分最高时的质构指标值Xmax,再将各品质特性的质构参数根据公式(1)转换为质构指标指数,用于主成分分析。

质构指标指数/%=[1−|Xi−Xmax (1) 式中,Xmax为感官得分最高时对应的理论质构指标参数;Xi为实际测量指标参数。

(2) 数据的综合评价:按照主成分累计方差贡献率大于85%的原则,选择主成分个数,以各主成分的方差贡献率与总方差贡献率的比值作为主成分权重系数,按(2)分析得到综合得分,按(3)规一化处理获质构综合指数。

综合得分 = \frac{{\sum\nolimits_{i = 1}^0 {\left( {{F_i} \cdot {W_i}} \right)} }}{{{W_{总}}}} (2) 式中,Fi表示各主成分的得分,Wi表示主成分相应的方差贡献率,W总表示主成分总的方差贡献率。

质构综合指数/\% = \frac{{F - {F_{\min }}}}{{{F_{\max }} - {F_{\min }}}} \times 100\% (3) 式中,F表示样品的综合得分,Fmin表示质构指标均为0时的理论综合得分,Fmax表示质构指标均为Xmax时的理论综合得分。

1.5 数据分析

采用SPSS19.0软件对试验数据进行单因素方差分析,Design-Expert 8.0.6软件进行响应面设计及分析。

2. 结果与分析

2.1 CaCl2质量浓度对海带质构品质的影响

由表 4可知,随着CaCl2质量浓度的增加,漂烫处理的海带硬度、弹性、内聚性、咀嚼性、胶着性、恢复性、胶着性及质构综合指数均呈先增加后趋于稳定的趋势,弹性呈一直增大的趋势,差异均达显著水平(P<0.05)。从经济成本考虑,适宜的CaCl2质量浓度应为1.5 g·L-1,可使不添加CaCl2的样品硬度、内聚性、咀嚼性、恢复性、胶着性及质构综合指数比照分别提高158.68%、18.75%、219.45%、42.10%、210.93%和245.59%。

表 4 CaCl2质量浓度对海带质构品质的影响Table 4. Effect of Ca2+ concentration on texture of kelp productCaCl2质量浓度/(g·L-1) 硬度/g 弹性 内聚性 咀嚼性/g 恢复性 胶着性/g 感官评分 质构综合指数 0 396.56±8.51c 0.82±0.01c 0.48±0.03b 154.08±8.69d 0.19±0.01c 188.46±9.92d 3.53 22.46±2.25d 0.5 852.13±50.97b 0.84±0.01b 0.58±0.02a 414.34±6.19c 0.27±0.00a 493.39±15.68c 6.75 67.25±0.59c 1.0 959.69±90.84ab 0.87±0.02a 0.57±0.02a 478.48±35.94b 0.28±0.01a 548.67±42.80ab 7.29 74.41±1.21b 1.5 1025.81±15.68a 0.84±0.01b 0.57±0.01a 492.21±5.40b 0.27±0.01a 585.98±3.26a 7.80 77.62±1.37a 2.0 1013.68±48.02a 0.87±0.01a 0.58±0.03a 513.34±4.09a 0.25±0.02b 592.29±1.04a 7.04 78.01±0.31a 2.5 1017.44±21.11a 0.87±0.00a 0.58±0.00a 514.58±15.67a 0.24±0.00b 590.11±23.51a 6.75 77.22±0.47a 注:同列数据后不同小写字母表示显著差异(P<0.05)。表 5、6同。 2.2 漂烫温度对海带质构品质的影响

由表 5可知,随着漂烫温度的增加,处理的海带硬度、咀嚼性、胶着性、感官评分及质构综合指数均呈先增加后减少的趋势,弹性、内聚性和恢复性呈始终下降的趋势,差异均达显著水平(P<0.05)。结果表明,适宜的漂烫温度为90℃,与未加热对照的海带产品相比,其硬度、咀嚼性、胶着性及质构综合指数可分别提高217.09%、244.91%、250.29%和272.26%。

表 5 漂烫温度对海带质构品质的影响Table 5. Effect of blanching temperature on texture of kelp product漂烫温度/℃ 硬度/g 弹性 内聚性 咀嚼性/g 恢复性 胶着性/g 感官评分 质构综合指数 60 723.01±37.10e 0.90±0.04a 0.65±0.01a 427.74± 33.70b 0.28±0.01a 473.46±28.13c 6.39 62.32±0.67c 70 1049.24± 57.79c 0.85±0.01ab 0.56±0.00b 498.08± 22.51a 0.28±0.01a 586.64± 36.76b 6.83 77.58±2.47b 80 1147.06± 15.61b 0.83±0.03b 0.54±0.01b 510.04± 13.38a 0.27±0.00a 613.06± 2.67b 7.31 79.01±1.76b 90 1257.44± 16.69a 0.81±0.01b 0.53±0.01b 531.43± 9.06a 0.27±0.00a 660.16± 15.63a 7.60 83.61±1.18a 100 871.37± 4.52d 0.76±0.01c 0.49±0.01c 322.99± 2.98c 0.21±0.01b 423.94± 10.21c 5.31 50.75±0.23d 2.3 漂烫时间对海带质构品质的影响

由表 6可见,随着漂烫时间的延长,处理的海带硬度、内聚性、咀嚼性、胶着性、感官评分及质构综合指数均呈先增加后减少的趋势,弹性和恢复性始终呈下降趋势,差异均达显著水平(P<0.05)。结果表明,漂烫时间为4 min时,样品硬度、内聚性、咀嚼性、胶着性及质构综合指数比对照分别提高86.28%、22.45%、123.29%、126.89%和107.44%。质构综合指数显著高于其他组(P<0.05)。

表 6 漂烫时间对海带质构品质的影响Table 6. Effect of blanching time on texture of kelp product漂烫时间/min 硬度/g 弹性 内聚性 咀嚼性/g 恢复性 胶着性/g 感官评分 质构综合指数 0 522.44± 50.91c 0.84±0.03a 0.49±0.04c 214.49± 5.93de 0.26±0.04a 255.97± 14.28d 5.01 36.01±2.34d 2 867.94± 50.35b 0.84±0.01a 0.56±0.01b 406.89± 17.21b 0.29±0.01a 483.00± 24.40b 6.44 66.45±1.02ab 4 973.19± 23.26ab 0.82±0.01ab 0.60±0.01a 478.94± 4.62a 0.23±0.01b 580.77± 0.46a 6.89 74.70±1.50a 6 1087.31± 105.38a 0.78±0.00bc 0.50±0.01c 419.52± 34.69b 0.19±0.01c 537.84± 44.48ab 7.95 62.95±4.67b 8 807.75± 135.53b 0.73±0.05cd 0.45±0.01d 265.79±57.87cd 0.16±0.01c 363.48± 55.45c 5.14 39.20±8.28cd 10 852.13± 191.53b 0.74±0.05cd 0.49±0.01c 300.59± 44.17c 0.19±0.01c 412.60± 86.87c 4.96 47.44±2.13c 2.4 响应面法试验设计结果及方差分析

通过Box-Behnken响应面优化漂烫工艺,采用Design-Expert 8.0.6软件对表 7试验数据进行多元回归拟合,获得质构综合指数(Y)与漂烫温度(X1)、CaCl2质量浓度(X2)、漂烫时间(X3)的回归模型方程为:Y=81.13-6.53X1-4.25X2+7.87X3+4.69X1X2-7.68X1X3+4.98X2X3-16.86X12-30.43X22-4.56X32。

表 7 响应面试验设计与结果Table 7. Design and results of response surface experiment序号 X1 X2 X3 质构综合指数 1 -1 -1 0 50.04 2 1 -1 0 26.30 3 -1 1 0 32.00 4 1 1 0 27.01 5 -1 0 -1 53.98 6 1 0 -1 57.58 7 -1 0 1 77.20 8 1 0 1 50.07 9 0 -1 -1 43.48 10 0 1 -1 25.17 11 0 -1 1 57.13 12 0 1 1 58.74 13 0 0 0 82.27 14 0 0 0 78.05 15 0 0 0 78.80 16 0 0 0 84.55 17 0 0 0 81.97 方差分析及显著性分析结果见表 8,一次项X1、X3,二次项X12、X22,交互项X1X3均达到极显著水平(P<0.01),X2达显著水平(P<0.05)。模型P<0.01,失拟项P>0.05,说明该模型可以准确反映实际生产中质构综合指数与工艺条件之间的影响关系。本试验范围内影响大小顺序依次为:漂烫时间(X3)>漂烫温度(X1)>CaCl2质量浓度(X2)。

表 8 响应面回归模型的方差分析Table 8. Analysis of variance on estimated regression model for correlations between independent variables andresponses方差来源 平方和 自由度 均方 F值 P值 显著性 模型 5263.71 9 584.86 34.68 <0.0001 ** X1 258.16 1 258.16 15.31 0.0058 ** X2 109.42 1 109.42 6.49 0.0383 * X3 374.18 1 374.18 22.19 0.0022 ** X1X2 66.40 1 66.40 3.94 0.0876 X1X3 178.48 1 178.48 10.58 0.0140 ** X2X3 74.98 1 74.98 4.45 0.0729 X12 904.71 1 904.71 53.65 0.0002 ** X22 2948.67 1 2948.67 174.86 <0.0001 ** X32 66.31 1 66.31 3.93 0.0878 残差 118.04 7 16.86 失拟项 96.38 3 32.13 5.93 0.0591 纯误差 21.66 4 5.42 综合 5381.76 16 注:*表示差异显著(P<0.05);**表示差异极显著(P<0.01)。 2.5 响应面交互作用分析

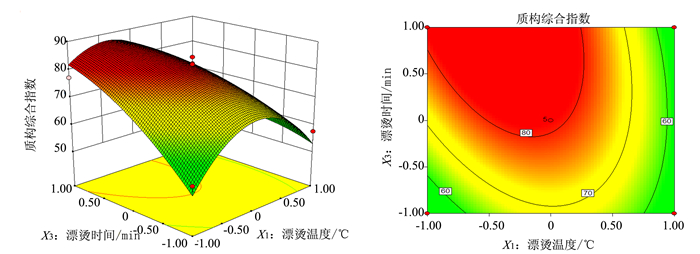

响应面是响应值对各因素所构成的三维空间曲面图,因素对响应值影响越大,曲面越陡峭[17]。而等高线的形状则可以反映两两因素之间交互作用的显著程度,椭圆形表示两因素交互作用显著,而圆形则表示两因素交互作用不显著[18-19]。固定CaCl2质量浓度为0水平值,得到漂烫温度与漂烫时间的交互作用对质构综合指数Y的影响的三维响应面图(图 1)。可以看出,漂烫温度与漂烫时间的交互作用对质构综合指数Y的影响显著。随着各因素值的增加,质构综合指数呈先增加后减小趋势。当漂烫温度X1在-1.00到-0.19水平、漂烫时间X3在-1.00到0.86水平时,海带质构综合指数Y与两因素的交互作用呈正相关关系;当X1在-0.19到1.00水平、X3在0.86到1.00水平时,海带质构综合指数Y与两因素的交互作用呈负相关关系。在达到中心点附近时响应值最大,此时海带的品质最好。后随着两者的增加质构综合指数呈现降低的趋势,海带的品质开始下降。

2.6 最优工艺的确定和验证

Design-Expert软件优化试验结果,得到海带钙盐漂烫处理的最佳条件:漂烫温度87.8℃,CaCl2质量浓度1.54 g·L-1,漂烫时间4.77 min。考虑生产可操作性,将优化条件校正为:漂烫温度88℃,CaCl2质量浓度1.54 g·L-1,漂烫时间4 min 40s。在此条件下进行验证试验,得到海带的质构综合指数为86.11±0.02,与理论预测值86.302 5的相对误差ξ为0.22%,差异不显著(P>0.05)。处理的海带产品组织紧密,质地脆嫩。

3. 讨论

褐藻胶是海带特有的酸性多糖,是由α-L-古罗糖醛酸(Guluronate,G)和β-D-甘露糖醛酸(Mannuronate,M)两种糖单元通过1, 4-糖苷键连续连接或交替连接聚合而形成的线性多糖分子[20],其钠盐形式为褐藻酸钠(Alginate)。褐藻胶及其钠盐是海带细胞壁之间最主要的填充物质,其生物功能主要是起到胞外的保护和支撑作用,填充细胞壁间的主要成分为甘露糖醛酸,而填充细胞壁的主要成分则是甘露糖醛酸和古罗糖醛酸混合组成或者单一古罗糖醛酸组成[21]。在热处理过程中海带易出现脱水现象,褐藻胶及其钠盐析出或被破坏,导致海带出现软化现象。已有研究表明海藻胶及其钠盐可与Ca2+等二价阳离子发生金属离子络合反应,使分子链交联缠绕形成具有三维网络结构,生成“锯齿型结构”、又称“蛋壳结构”的不溶性凝胶[22-23],使组织结构变紧密。因此,可对海带进行钙盐硬化处理,以使其在加热后肉质口感仍带有一定的硬度和脆性[24]。CaCl2质量浓度、反应温度和时间是钙盐处理的主要影响因素。适宜的CaCl2质量浓度、漂烫温度和时间均可促进溶液中的Ca2+与细胞壁和细胞膜中的海藻胶分子反应,形成具有三维网络结构的凝胶,结构紧密,硬度、脆度等质构指标增加。但当Ca2+浓度过量时,多余的钙盐会堵塞细胞间隙,在一定程度上阻碍了Ca2+继续与海藻酸钠古罗糖醛酸上的羧基结合[25-26],因此当CaCl2质量浓度超过1.5 g·L-1后海带漂烫后的质构品质不再发生显著改变。反应温度过高、时间过长时,过度的加热会使海藻酸钙凝胶体系的结构被破坏,使海带开始出现质构松弛、咀嚼感下降等现象。漂烫温度和时间的交互作用影响达极显著,说明漂烫温度和时间对海带产品硬度、弹性、内聚性、咀嚼性、恢复性、胶着性等产生互作效应。因此,在海带发酵饮料、海带泡菜等新产品的实际生产过程中,须对产品的适宜杀菌工艺进行进一步研究[27],使杀菌后海带的质构综合指数控制在适宜的水平。

4. 结论

本研究证明了钙盐漂烫处理可提高海带热处理的质构品质,以质构综合指数为考察指标,通过单因素及响应面优化试验,得出漂烫温度(X1)、CaCl2质量浓度(X2)、漂烫时间(X3)对质构综合指数(Y)的影响符合数学模型:Y=81.13-6.53X1-4.25X2+7.87X3+4.69X1X2-7.68X1X3+4.98X2X3-16.86X12-30.43X22-4.56X32。影响质构品质的因素顺序依次为:漂烫时间>漂烫温度>CaCl2质量浓度。漂烫温度与漂烫时间对质构综合指数影响的交互作用达显著水平。参数寻优为:漂烫时间4 min 40 s,CaCl2质量浓度1.54 g·L-1,漂烫温度87.9℃。在此条件下,海带质构综合指数为86.11±0.02,与预测值相比,差异不显著(P>0.05)。通过对海带进行Ca2+处理,不仅可解决海带加工过程中易软化的技术瓶颈,还可进一步开发海带发酵饮料、海带泡菜等新产品,具有广阔的应用前景。

-

表 1 响应面试验设计因素与水平

Table 1 Factors and levels of response surface experimental design

因素 编码 水平 -1 0 1 漂烫温度/℃ X1 85 90 95 CaCl2质量浓度/(g·L-1) X2 1.0 1.5 2.0 漂烫时间/min X3 3 4 5 表 2 感官评分标准

Table 2 Criteria for sensory evaluation

项目 很好 较好 一般 差 质地 藻体均匀,组织紧密,质地脆嫩 藻体均匀,组织紧密,质地较脆嫩 藻体不均匀,组织过紧密或松弛,质地略硬或略软 藻体不均匀,组织过紧密或松弛,质地过硬 色泽 均匀,表面有光泽,不暗淡 均匀,表面有光泽,光泽度略差 不均匀,色泽暗淡,光泽度略差 不均匀,色泽很暗淡,光泽度很差 气味 藻香味浓郁,无异味 藻香味明显,无异味 有轻微藻香味,有异味 藻香味不浓,异味严重 口味 无苦涩味,海带味正常 无苦涩味,海带味道略不正常 略有苦涩味,海带味道不正常 苦涩味明显,有异味 表 3 各等级的轶值

Table 3 Proliferation valuesforproduct grading

很好 较好 一般 差 分值 7~10 5~7 3~5 1~3 轶 8.5 6 4 2 表 4 CaCl2质量浓度对海带质构品质的影响

Table 4 Effect of Ca2+ concentration on texture of kelp product

CaCl2质量浓度/(g·L-1) 硬度/g 弹性 内聚性 咀嚼性/g 恢复性 胶着性/g 感官评分 质构综合指数 0 396.56±8.51c 0.82±0.01c 0.48±0.03b 154.08±8.69d 0.19±0.01c 188.46±9.92d 3.53 22.46±2.25d 0.5 852.13±50.97b 0.84±0.01b 0.58±0.02a 414.34±6.19c 0.27±0.00a 493.39±15.68c 6.75 67.25±0.59c 1.0 959.69±90.84ab 0.87±0.02a 0.57±0.02a 478.48±35.94b 0.28±0.01a 548.67±42.80ab 7.29 74.41±1.21b 1.5 1025.81±15.68a 0.84±0.01b 0.57±0.01a 492.21±5.40b 0.27±0.01a 585.98±3.26a 7.80 77.62±1.37a 2.0 1013.68±48.02a 0.87±0.01a 0.58±0.03a 513.34±4.09a 0.25±0.02b 592.29±1.04a 7.04 78.01±0.31a 2.5 1017.44±21.11a 0.87±0.00a 0.58±0.00a 514.58±15.67a 0.24±0.00b 590.11±23.51a 6.75 77.22±0.47a 注:同列数据后不同小写字母表示显著差异(P<0.05)。表 5、6同。 表 5 漂烫温度对海带质构品质的影响

Table 5 Effect of blanching temperature on texture of kelp product

漂烫温度/℃ 硬度/g 弹性 内聚性 咀嚼性/g 恢复性 胶着性/g 感官评分 质构综合指数 60 723.01±37.10e 0.90±0.04a 0.65±0.01a 427.74± 33.70b 0.28±0.01a 473.46±28.13c 6.39 62.32±0.67c 70 1049.24± 57.79c 0.85±0.01ab 0.56±0.00b 498.08± 22.51a 0.28±0.01a 586.64± 36.76b 6.83 77.58±2.47b 80 1147.06± 15.61b 0.83±0.03b 0.54±0.01b 510.04± 13.38a 0.27±0.00a 613.06± 2.67b 7.31 79.01±1.76b 90 1257.44± 16.69a 0.81±0.01b 0.53±0.01b 531.43± 9.06a 0.27±0.00a 660.16± 15.63a 7.60 83.61±1.18a 100 871.37± 4.52d 0.76±0.01c 0.49±0.01c 322.99± 2.98c 0.21±0.01b 423.94± 10.21c 5.31 50.75±0.23d 表 6 漂烫时间对海带质构品质的影响

Table 6 Effect of blanching time on texture of kelp product

漂烫时间/min 硬度/g 弹性 内聚性 咀嚼性/g 恢复性 胶着性/g 感官评分 质构综合指数 0 522.44± 50.91c 0.84±0.03a 0.49±0.04c 214.49± 5.93de 0.26±0.04a 255.97± 14.28d 5.01 36.01±2.34d 2 867.94± 50.35b 0.84±0.01a 0.56±0.01b 406.89± 17.21b 0.29±0.01a 483.00± 24.40b 6.44 66.45±1.02ab 4 973.19± 23.26ab 0.82±0.01ab 0.60±0.01a 478.94± 4.62a 0.23±0.01b 580.77± 0.46a 6.89 74.70±1.50a 6 1087.31± 105.38a 0.78±0.00bc 0.50±0.01c 419.52± 34.69b 0.19±0.01c 537.84± 44.48ab 7.95 62.95±4.67b 8 807.75± 135.53b 0.73±0.05cd 0.45±0.01d 265.79±57.87cd 0.16±0.01c 363.48± 55.45c 5.14 39.20±8.28cd 10 852.13± 191.53b 0.74±0.05cd 0.49±0.01c 300.59± 44.17c 0.19±0.01c 412.60± 86.87c 4.96 47.44±2.13c 表 7 响应面试验设计与结果

Table 7 Design and results of response surface experiment

序号 X1 X2 X3 质构综合指数 1 -1 -1 0 50.04 2 1 -1 0 26.30 3 -1 1 0 32.00 4 1 1 0 27.01 5 -1 0 -1 53.98 6 1 0 -1 57.58 7 -1 0 1 77.20 8 1 0 1 50.07 9 0 -1 -1 43.48 10 0 1 -1 25.17 11 0 -1 1 57.13 12 0 1 1 58.74 13 0 0 0 82.27 14 0 0 0 78.05 15 0 0 0 78.80 16 0 0 0 84.55 17 0 0 0 81.97 表 8 响应面回归模型的方差分析

Table 8 Analysis of variance on estimated regression model for correlations between independent variables andresponses

方差来源 平方和 自由度 均方 F值 P值 显著性 模型 5263.71 9 584.86 34.68 <0.0001 ** X1 258.16 1 258.16 15.31 0.0058 ** X2 109.42 1 109.42 6.49 0.0383 * X3 374.18 1 374.18 22.19 0.0022 ** X1X2 66.40 1 66.40 3.94 0.0876 X1X3 178.48 1 178.48 10.58 0.0140 ** X2X3 74.98 1 74.98 4.45 0.0729 X12 904.71 1 904.71 53.65 0.0002 ** X22 2948.67 1 2948.67 174.86 <0.0001 ** X32 66.31 1 66.31 3.93 0.0878 残差 118.04 7 16.86 失拟项 96.38 3 32.13 5.93 0.0591 纯误差 21.66 4 5.42 综合 5381.76 16 注:*表示差异显著(P<0.05);**表示差异极显著(P<0.01)。 -

[1] 宋武林.海带的主要功能及加工利用研究现状[J].渔业研究, 2016, 38(1):81-86. http://www.cnki.com.cn/Article/CJFDTOTAL-MLZW201404022.htm [2] 董金和. 《2013中国渔业统计年鉴》解读[J].农产品市场周刊, 2013(24):19-20. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zhongguosc201307010 [3] 王庆佳, 李智, 郑宝东, 等.海带酥性饼干的研制及血糖生成指数评价[J].食品研究与开发, 2016, 37(7):184-188. http://www.cnki.com.cn/Article/CJFDTOTAL-JDXZ200402022.htm [4] 黄震. 一种盐渍海带的加工方法: 中国, CN201610763490. X[P]. 2017-1-4. [5] 漳州金浦三源食品实业有限公司. 一种海带卷生产线: 中国, CN201520862613. 6[P]. 2016-5-11. [6] 樊琳, 娄永江, 陈小芳, 等.亚微米级海带粉制备技术研究及物理特性分析[J].核农学报, 2016, 30(1):120-129. DOI: 10.11869/j.issn.100-8551.2016.01.0120 [7] 刘建福.即食调味海带结生产工艺研究[J].食品工业科技, 2005(4):108-110. https://www.wenkuxiazai.com/doc/bb63a68371fe910ef12df809.html [8] 王存堂, 杨丽, 蒋继丰, 等.魔芋海带丝保健食品的研制[J].食品工业科技, 2008(11):198-200. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=spgykj200811062 [9] 江晓宁, 陈钏杰, 沈宇丹, 等.海带的加工技术与研究现状[J].北京农业, 2015(12):22. DOI: 10.3969/j.issn.1000-6966.2015.12.015 [10] 肖欣欣, 陈丽娇, 程艳, 等.海带泡菜自然发酵工艺[J].食品与发酵工业, 2011, 37(12):96-99. http://www.cqvip.com/QK/93201X/201112/40845316.html [11] 廖华. 聚糖醛酸与钙离子的络合机理及其凝胶化调控[D]. 武汉: 湖北工业大学, 2016. [12] GOMEZ C G, PÉREZ LAMBERCHT M V, LOZANO J E, et al. Influence of the extraction-purification conditions on final properties of alginates obtained from brown algae (Macrocystis pyrifera)[J]. International Journal of Biological Macromolecules, 2009, 44(4):365-371. DOI: 10.1016/j.ijbiomac.2009.02.005

[13] 李伟, 郜海燕, 陈杭君, 等.基于主成分分析的不同品种杨梅果实综合品质评价[J].中国食品学报, 2017, 17(6):161-171. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jlnydxxb201405014 [14] 杨文婷, 李俊丽, 孔丰, 等.基于主成分分析法对冷冻滩羊肉品质评价模型的构建[J].食品工业科技, 2017, 38(9):300-303, 313. http://fjks.cbpt.cnki.net/WKB/WebPublication/wkTextContent.aspx?contentID=58f6d35c-3ff8-4f35-94c7-c7c087c41986&mid=fjks [15] JIN X, WU X, LIU X, et al. Varietal heterogeneity of textural characteristics and their relationship with phenolic ripeness of wine grapes[J]. Scientia Horticulturae, 2017, 216:205-214. DOI: 10.1016/j.scienta.2017.01.010

[16] 王红丽, 陈慎, 何志刚, 等.基于主成分分析法的钙盐漂烫海带质构品质综合评价[J].福建农业学报, 2017, 32(10):1124-1129. http://www.fjnyxb.cn/CN/article/downloadArticleFile.do?attachType=PDF&id=3285 [17] 杨英, 何璐, 向忠琪, 等.海藻酸钠与钙离子对大米淀粉糊化的影响[J].中国粮油学报, 2017, 32(2):37-42. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1112862 [18] THANA P, MACHMUDAH S, GOTO M, et al. Response surface methodology to supercritical carbon dioxide extraction of astaxanthin from Haematococcus pluvialis[J].Bioresource Technology, 2008, 99(8):3110-3115. DOI: 10.1016/j.biortech.2007.05.062

[19] 张杰, 侯潞丹, 贺志斌, 等.响应面试验优化杏鲍菇液体发酵菌种培养条件[J].食品科学, 2017, 38(6):147-152. DOI: 10.7506/spkx1002-6630-201706023 [20] SILVA E D O, BORGES L L, CONCEIÃO E C D, et al. Box-Behnken experimental design for extraction of artemisinin from Artemisia annua, and validation of the assay method[J]. Revista Brasileira De Farmacognosia, 2017, 27(4):519-524. DOI: 10.1016/j.bjp.2017.03.002

[21] DAVEY R B, SPARNON A L, BYARD R W. Unusual donor site reactions to calciuM alginate dressings[J].Burns, 2000, 26(4):393. DOI: 10.1016/S0305-4179(99)00140-0

[22] 王忍. 海带(Saccharina japonica)褐藻胶合成途径若干基因的克隆、表达以及功能图验证[D]. 青岛: 中国海洋大学, 2014: 5-6. [23] YANG J S, XIE Y J, HE W. Research progress on chemical modification of alginate:A review[J]. Carbohydrate polymers, 2011, 84(1):33-39. DOI: 10.1016/j.carbpol.2010.11.048

[24] BORGOGNA M, SKJÅK BRAE K G, PAOLETTI S, et al. On the initial binding of alginate by calcium ions:The tilted egg-box hypothesis[J]. Journal of Physical Chemistry B, 2013, 117(24):7277-7282. DOI: 10.1021/jp4030766

[25] 张予心, 蔡丹, 宋秋梅, 等.乳清蛋白与海藻酸钠复合物凝胶特性的影响因素[J].中国食品学报, 2017, 17(5):40-48. http://mall.cnki.net/magazine/Article/RPGY201406004.htm [26] LU J, YANG H, HAO J, et al. Impact of hydrolysis conditions on the detection of mannuronic to guluronic acid ratio in alginate and its derivatives[J]. Carbohydrate Polymers, 2015, 122:180-188. DOI: 10.1016/j.carbpol.2015.01.008

[27] 郭鸿华. 即食海带产品开发及其生产线设计[D]. 福州: 福建农林大学, 2017: 9-10. -

期刊类型引用(1)

1. 陈秉彦,林晓姿,李维新,窦芳娇,何志刚. 海带泡菜货架期质构品质的钠钙比调控机制. 食品科学. 2023(23): 23187-23193 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: