Process Optimization and Antimicrobial Activity of Natural Preservative Extracted from Bamboo Sawdust

-

摘要:目的 为研究竹屑制备天然防腐剂的最优工艺并探讨其抑菌性能。方法 以竹屑为原料,采用乙酸乙酯回流法,在单因素试验基础上,应用响应面法优化天然防腐剂制备条件,并考察其抑菌活性。结果 竹屑制备天然防腐剂的最佳工艺条件为超声功率300 W、提取温度89℃、液料比20 ∶ 1、提取时间2 h。在此条件下,所得提取物对大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉的抑菌效果达到最强,抑菌圈直径分别为:9.33、15.67、10.00、6.67 mm,最低抑菌浓度分别为:0.025 00、0.012 50、0.050 00和0.100 00 g·mL−1,竹屑天然防腐剂得率为4.77%。结论 响应面法优化工艺制备的天然防腐剂对4种供试菌抑菌效果良好,制备工艺可行性高。该工艺可为竹废弃物的加工再利用提供参考。Abstract:Objective Optimum preparation and antibacterial properties of a natural preservative extracted from bamboo sawdust were studied.Method Utilizing bamboo sawdust, a natural preservative was prepared with the ethyl acetate reflux method. Processing conditions were optimized by the response surface methodology based on the results of a single factor test. In vitro antimicrobial activity of the extract was determined.Result The finalized process applied 300 W ultrasonic power on the mixture of solvent-to-substrate ratio at 20 ∶ 1 to extract at 89℃ for 2 h. The product yield reached 4.77%. The extracted preservative displayed peak antimicrobial effects on Escherichia coli, Staphylococcus aureus, Bacillus subtilis and Aspergillus niger with the average inhibition diameters of 9.33 mm at a concentration of 0.025 00 g·mL−1, 15.67 mm at a concentration of 0.012 5 0g·mL−1, 10.00 mm at a concentration of 0.050 00 g·mL−1, and 6.67 mm at a concentration of 0.100 00 g·mL−1, respectively.Conclusion The natural preservative prepared by the newly developed extraction method showed strong in vitro antimicrobial effect, and the optimized process could be upscaled to fully utilize the bamboo sawdust.

-

0. 引言

【研究意义】中国竹种类丰富多样,竹林面积、蓄积量和产量均居世界之首。第八次全国资源连续清查报告表明,我国竹林面积已达601万hm2[1],是重要的森林资源之一。材用竹广泛应用于建筑、家具、造纸和工艺品等行业,在竹加工产业中,产生的废弃物约占整个竹产品的60%以上,这些“废料”的丢弃导致竹材的利用率始终停留在35%~40%这一阶段[2]。【前人研究进展】相关研究表明,毛竹采伐剩余物主要由纤维素、半纤维素和木质素组成,经硫酸盐法成浆后,纸浆得率为44.71%[3]。目前竹屑的资源化利用形式主要有直接利用、传统加工利用和工业化利用,产品主要包括复合材料[4]、生物质燃料[5-6]、活性炭[7-9]、食用菌基质[10]和多糖[11-12]等。此外,竹屑中还含有蛋白质、脂肪、糖、矿物质和多种次生代谢产物,含量因竹种、竹部位、采伐季节以及生长环境而异[13-14]。从植物的次生代谢产物中获取天然的抗菌成分,一直是国内外天然防腐剂的研究热点[15-17]。【本研究切入点】天然植物源防腐剂提取工艺复杂、成本高、生产季节性强,是影响其获取和广泛应用的限制性因素。竹屑为竹产业加工的废弃物,且资源丰富,以竹屑为原料制备天然防腐剂应用于抗菌领域的研究鲜见报道。【拟解决的关键问题】以竹屑为原料,采用简便、可行性高的乙酸乙酯回流法制备天然植物源防腐剂,通过响应面法优化提取工艺,并考察其对食品中常见有害微生物的抑制作用。期望本研究结果能为低毒天然植物源防腐剂的研发奠定基础。

1. 材料与方法

1.1 材料与设备

将竹废弃物收集于武夷山竹加工厂,用高速中药粉碎机粉碎,过60目筛,制成竹屑,备用;大肠杆菌(Escherichia coli)、金黄色葡萄球菌(Staphylococcus aureus)、枯草芽孢杆菌(Bacillus subtilis)、黑曲霉(Aspergillus niger),均为武夷学院生物工程实验室保藏菌种;乙酸乙酯、硝酸钠和磷酸氢二钾等分析纯试剂,琼脂粉、牛肉膏和蛋白胨等生化试剂,均购自上海麦克林生化科技有限公司。

103B型高速中药粉碎机(永历制药机械有限公司);BSA 223S电子天平(赛多利斯科学仪器有限公司);R206D旋转蒸发仪(上海申生科技有限公司);LG-1002-A型超净工作台(苏州真田洁净设备有限公司);生化培养箱(上海精宏实验设备有限公司);KQ-500D型数控超声波清洗器(瑞利仪器分析有限公司)。

1.2 试验方法

1.2.1 竹屑制备天然防腐剂的单因素试验

称取5.0 g竹屑,在液料比为20∶1(mL∶g)的乙酸乙酯溶液,超声功率分别为100 W、200 W、300 W、400 W的条件下超声1 h,于90℃的热水浴中进行2 h的回流提取,提取2次。将提取液合并后,在旋转蒸发仪上减压浓缩至黏稠状,将浓缩提取液在真空干燥箱中干燥成粉末后进行称重。分别测定不同功率超声波处理下所得提取物对大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉的抑菌效果,计算得率(得率/%=提取所得天然防腐剂干重/竹屑质量×100)。将优选的最佳超声功率作为固定参数,依次进行提取时间(1 h、2 h、3 h、4 h、5 h),液料比(10∶1、15∶1、20∶1、25∶1、30∶1),提取温度(60℃、70℃、80℃、90℃、100℃)对制备产物抑菌效果的单因素试验。试验均重复3次,取平均值。

1.2.2 响应面法优化竹屑制备天然防腐剂工艺试验

在单因素试验的基础上,根据Box-Behnken中心组合试验设计原理[18],在固定功率300 W超声1 h、提取2次的基础上,选取提取温度、液料比、提取时间3个因素,以大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉为指示菌,抑菌圈直径为响应值,对试验结果进行分析。试验因素及水平见表1。

表 1 Box-Behnken试验设计的因素及水平Table 1. Factors and levels of Box-Behnken experimental design水平

Level提取温度

Extraction temperature/℃液料比

Solvent-to-substrate ratio/(mL:g)提取时间

Extraction time/h−1 80 15∶1 1 0 90 20∶1 2 1 100 25∶1 3 1.2.3 防腐剂抑菌效果的试验与评价

菌悬液的制备:在无菌条件下用划线法分别将保藏的大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉菌种接种于相应的固体斜面培养基上,放入培养箱中,细菌在37℃下培养24 h、霉菌在28℃下培养48 h进行活化。挑取活化好的菌落,用无菌生理盐水10倍稀释法制得不同稀释浓度的菌悬液,菌落计数调整菌浓度为1×106~1×107 CFU·mL−1[19-20],备用。

抑菌圈直径的测定:取配制好的菌悬液各100 μL,均匀涂布在相应的无菌平板培养基上。将已灭菌烘干、直径为6.0 mm的圆滤纸片放入1 g·mL−1竹屑天然防腐剂溶液中浸泡30 min,取出后贴在含菌平板上[21],以无菌生理盐水作为空白对照。含大肠杆菌、金黄色葡萄球菌和枯草芽孢杆菌的平板在37℃恒温培养24 h,含黑曲霉的平板在28℃恒温培养48 h,之后取出测量抑菌圈直径大小,每个抑菌圈在垂直方向上测两次,每个试验重复3次,取其平均值。抑菌圈直径越大,则抑菌效果越好。

最低抑菌浓度值的测定:采用两倍稀释法测定竹屑天然防腐剂的最低抑菌浓度值(Minimal inhibitory concentration, MIC)。将竹屑天然防腐剂稀释成0.200 00、0.100 00、0.050 00、0.025 00、0.012 50、0.006 25 g·mL−1共6种质量浓度,以无菌生理盐水作为空白对照,重复滤纸片抑菌法,以出现抑菌圈的最小浓度为最低抑菌浓度值[22-23]。

2. 结果与分析

2.1 竹屑制备天然防腐剂的单因素试验

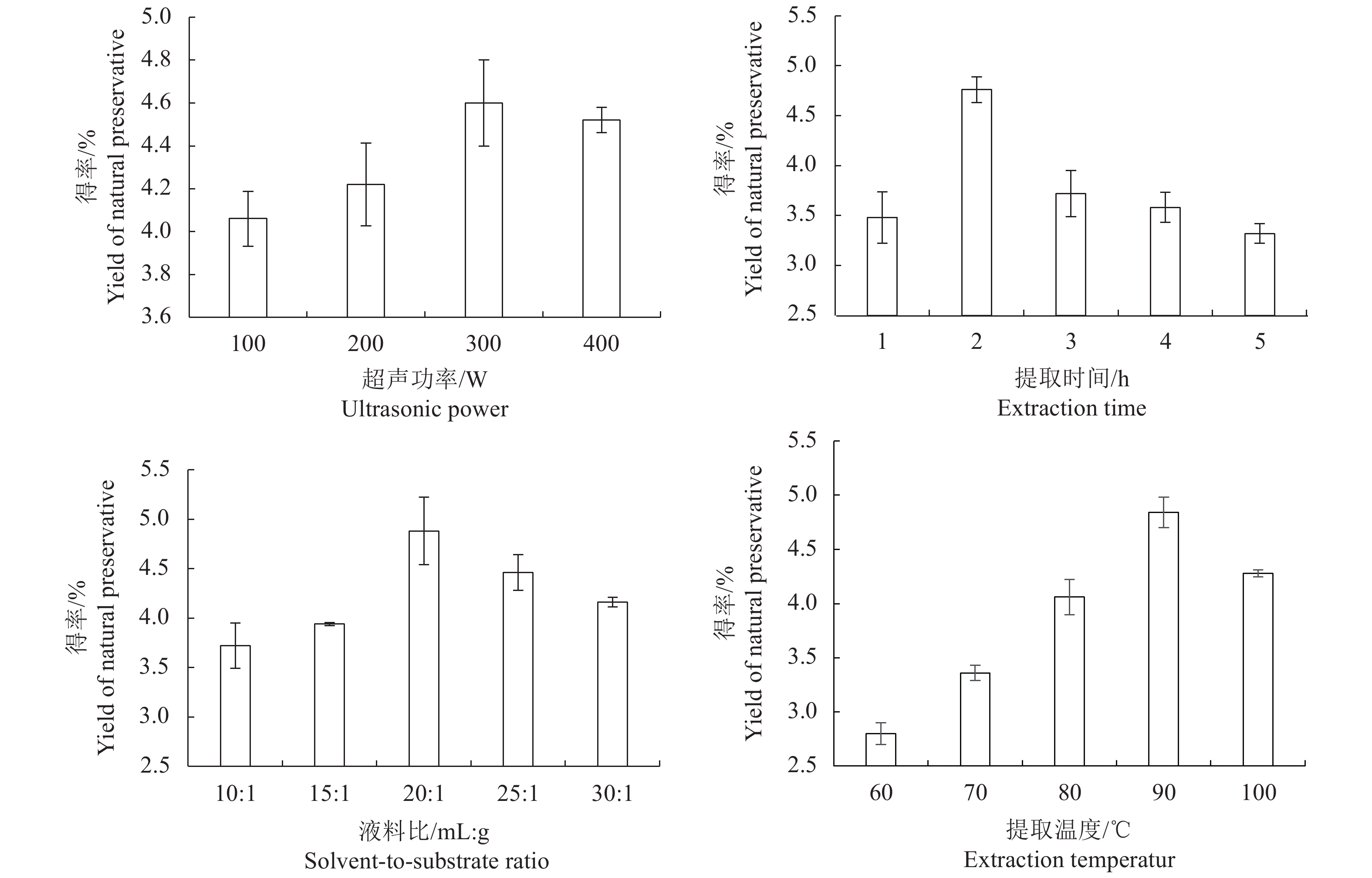

以4种供试菌抑菌圈直径大小为指标,分析超声功率、提取时间、液料比和提取温度对竹屑制备天然防腐剂的影响(图1),结果表明:当超声功率为300 W时,竹屑制备所得天然防腐剂对大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉的抑菌效果达到最大,抑菌圈直径分别为8.75 mm、16.00 mm、11.75 mm和7.25 mm。超声功率过大时,因空化和机械作用过强,破坏了活性物质的稳定性,故超声提取功率以300 W为宜。

由图1看出,随着提取时间的延长,提取物抑菌活性呈现先上升后下降的趋势,当乙酸乙酯回流提取时间为2 h时4种供试菌的抑菌圈直径同时达到最大值。考虑此时活性物质已充分溶解,故随后的抑菌活性不随提取时间增加而增加,说明合适的提取时间为2 h。

液料比从10∶1提高到20∶1,提取物抑菌活性逐渐升高,对金黄色葡萄球菌形成的抑菌圈直径可达17.00 mm。继续增加液料比,其抑菌活性略有下降,且乙酸乙酯溶液用量增加会使制备成本提高,故确定最适宜的液料比为20∶1。

提取物抑菌活性在90℃时达到峰值,继续提高温度,会加速抑菌活性成分的降解,导致提取物活性降低。因此,回流提取温度以90℃最佳。

进一步对在不同超声功率、提取时间、液料比和提取温度条件下,竹屑天然防腐剂得率进行考察。结果表明,最合适的天然防腐剂制备条件与抑菌圈直径结果一致。在其他条件固定的情况下,竹屑天然防腐剂的最佳制备条件为超声功率300 W、提取时间2 h、液料比20∶1和提取温度90℃,所得产物得率分别为4.60%、4.76%、4.88%和4.84%(图2)。在各单因素试验结果中,超声功率对竹屑天然防腐剂得率影响最小,不同参数下提取物得率最小为4.06%、最大为4.60%,故取固定超声功率300 W进行其他因素的响应面分析。

2.2 响应面法优化竹屑制备天然防腐剂工艺试验回归模型的建立与方差分析

在单因素试验的基础上,选择提取温度(A)、液料比(B)、提取时间(C)为影响因素,抑菌圈直径(y)为评价指标,设计三因素三水平响应面分析试验,结果见表2。利用Design-Expert 8.0.6软件对试验数据进行回归分析(表3),得到抑菌圈直径对提取温度(

A)、液料比(B)、提取时间(C)的数学回归模型为:y=10.48−0.6A+0.11B+1.12C−0.53AB+0.39AC+0.15BC−3.55A2−2.75B2−3.09C2。 表 2 响应面试验设计组合及结果Table 2. Design combinations and results of response surface test试验号

Test numberA提取温度

Extraction temperature/℃B液料比

Solvent-to-substrate ratio/(mL:g)C提取时间

Extraction time/h抑菌圈直径 Inhibitory zone diameter/mm 大肠杆菌

E. coli金黄色葡萄球菌

S. aureus枯草芽孢杆菌

B. subtilis黑曲霉

A. niger平均值

Average1 80 15∶1 2 3.75 6.79 2.50 3.21 4.06 2 100 15∶1 2 2.82 3.42 6.59 4.21 4.26 3 80 25∶1 2 4.24 7.41 5.38 3.58 5.15 4 100 25∶1 2 3.22 2.80 4.80 2.19 3.25 5 80 20∶1 1 3.50 8.56 1.88 2.70 4.16 6 100 20∶1 1 1.20 2.02 2.75 1.26 1.81 7 80 20∶1 3 4.58 8.96 3.02 3.76 5.08 8 100 20∶1 3 3.82 4.41 5.56 3.41 4.30 9 90 15∶1 1 2.52 3.86 4.00 2.42 3.20 10 90 25∶1 1 3.15 4.02 4.22 1.78 3.29 11 90 15∶1 3 5.49 6.54 6.78 3.92 5.68 12 90 25∶1 3 5.86 7.64 8.42 3.60 6.38 13 90 20∶1 2 8.75 16.02 10.51 7.25 10.63 14 90 20∶1 2 9.75 14.03 11.00 7.47 10.56 15 90 20∶1 2 7.75 14.98 10.03 7.01 9.94 16 90 20∶1 2 9.25 15.54 10.35 7.34 10.62 17 90 20∶1 2 9.15 16.40 9.90 7.21 10.67 表 3 响应面方差分析Table 3. Variance analysis of response surfaces差异来源

Source平方和

Sun of quares自由度

Degree of freedom均方

Mean squareF值

F valueP值

P value模型 Model 154.75 9 17.19 94.18 <0.000 1** A-提取温度Extraction temperature 2.92 1 2.92 15.97 0.005 2** B-液料比Solvent-to-substrate ratio 0.095 1 0.095 0.52 0.494 9 C-提取时间Extraction time 10.08 1 10.08 55.21 0.000 1** AB 1.1 1 1.1 6.04 0.043 6* AC 0.62 1 0.62 3.38 0.108 8 BC 0.093 1 0.093 0.51 0.498 4 A2 53.12 1 53.12 290.98 <0.000 1** B2 31.89 1 31.89 174.67 <0.000 1** C2 40.32 1 40.32 220.85 <0.000 1** 残差 Residual 1.28 7 0.18 失拟项 Lack of fit 0.9 3 0.3 3.2 0.145 5 纯误差 Pure error 0.38 4 0.094 总和 Total 156.03 16 注:*表示显著差异,P<0.05;**表示极显著差异,P<0.01。

Note: * P<0.05, the difference is significant at 0.05 level; ** P<0.01, the difference is significant at 0.01 level.对该模型进行方差分析可知,模型 P <0.000 1,表明回归模型高度显著。失拟项 P =0.145 5,表明试验拟合度较好,可用此模型进行分析和预测。模型的相关系数 r=0.995 9,校正决定系数 RAdj2=0.981 3,说明选用的模型与实际情况拟合较好、误差小,设计合理可靠,能较好地反映出各因素与抑菌圈平均直径之间的关系。各因素之间存在一定的交互作用,其中A、C、A2、B2、C2呈极显著影响(P<0.01),AB呈显著影响(P<0.05),B、AC、BC均呈不显著影响。由此可知,各因素对抑菌圈平均直径的影响不是简单的线性关系[24]。由F值可知,在试验范围内各因素对竹屑天然防腐剂抑菌效果的影响大小依次为:C(提取时间)>A(提取温度)>B(液料比)。

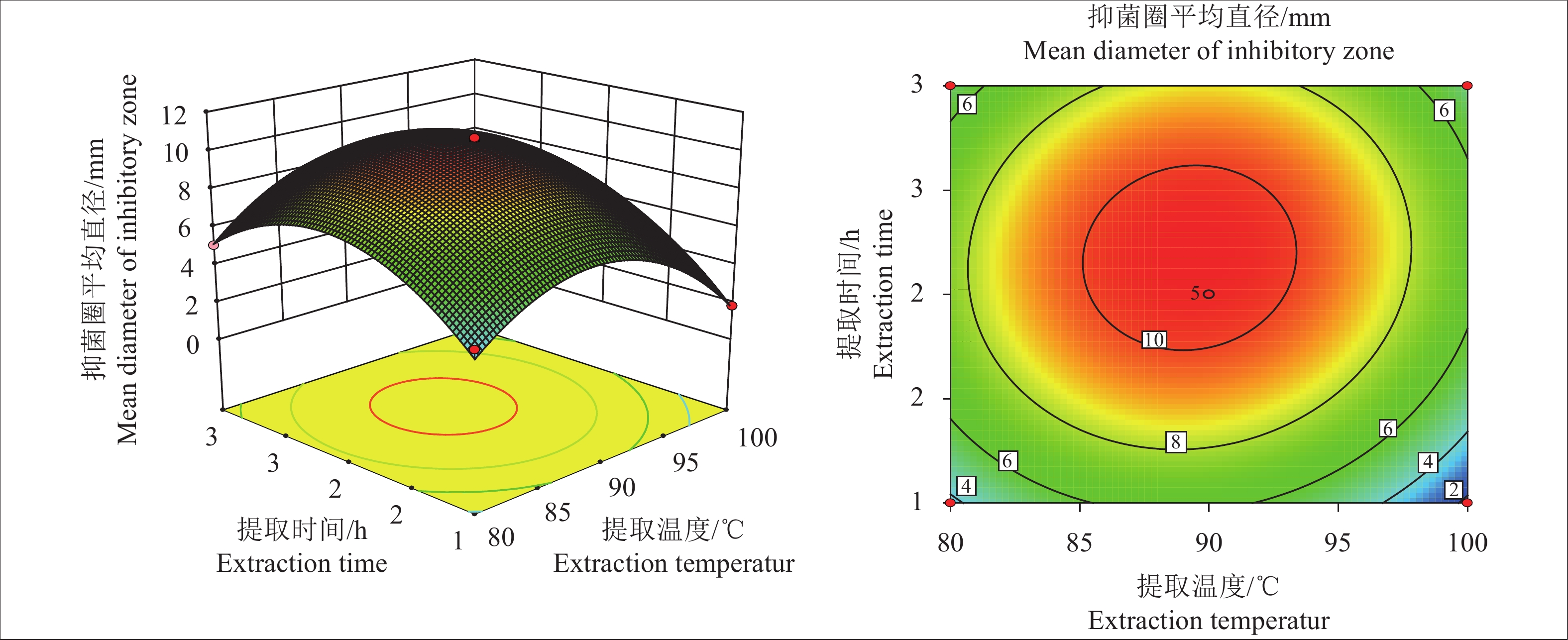

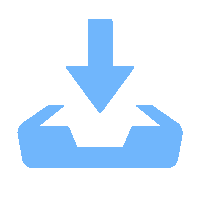

2.3 响应曲面图分析

在三因素之间两两交互作用的响应曲面图和等高线图(图3~5)中,响应面曲线走势越陡影响越显著,曲线走势越平滑影响越小;等高线的形状圆形或椭圆形反应的是交互效应的强弱程度,圆形代表交互作用不显著,椭圆形则代表交互作用显著[25]。由图3~5可知,在各单因素试验设置的水平范围内均存在极值,提取时间对抑菌圈平均直径的影响最大,提取温度和液料比的交互作用显著(P<0.05),与方差分析结果一致。

2.4 提取工艺优化及验证试验

根据数学回归模型得到竹屑天然防腐剂的最佳制备工艺条件为:提取温度89℃、液料比20∶1、提取时间2 h,在此工艺条件下,所获得的提取物对大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉的抑菌效果达到最大,理论抑菌圈平均直径可达10.61 mm。在此条件下,确定提取功率300 W,乙酸乙酯回流提取2次,进行3次平行试验验证,得到实际抑菌圈平均直径为(10.42±0.425)mm,与理论预测值相近。此条件下,竹屑天然防腐剂得率为(4.77±0.041)%。

2.5 最低抑菌浓度值的测定

采用试管二倍稀释法结合滤纸片法测定最优工艺所得竹屑天然防腐剂最低抑菌浓度值(表4),结果表明:大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉均对竹屑制备的天然防腐剂敏感。其中,金黄色葡萄球菌对提取物高度敏感,最低抑菌浓度为0.012 50 g·mL−1;大肠杆菌和枯草芽孢杆菌对竹屑制备的天然防腐剂中度敏感,最低抑菌浓度分别为0.025 00和0.050 00 g·mL−1;黑曲霉对竹废弃物制备的防腐剂敏感度较低,最低抑菌浓度为0.100 00 g·mL−1。

表 4 最低抑菌浓度的测定Table 4. Determination of minimal inhibitory concentration for peak antimicrobial effect抑菌浓度

Concentration /g·mL−1抑菌圈直径 Inhibitory zone diameter/mm 大肠杆菌

E. coli金黄色葡萄球菌

S. aureus枯草芽孢杆菌

B. subtilis黑曲霉

A. niger0.200 00 5.24±0.83 8.06±0.62 7.64±0.85 4.06±0.72 0.100 00 4.38±0.77 6.42±0.81 5.32±0.76 1.04±0.18 0.050 00 2.18±0.22 5.02±0.57 2.14±0.35 0.00 0.025 00 1.15±0.14 3.02±0.42 0.00 0.00 0.012 50 0.00 1.04±0.15 0.00 0.00 0.006 25 0.00 0.00 0.00 0.00 空白对照 Blank control 0.00 0.00 0.00 0.00 3. 讨论与结论

分别通过单因素试验和响应面优化试验得到竹屑制备天然植物源防腐剂的最佳工艺条件为:采用乙酸乙酯回流法,在超声功率300 W、提取温度89℃、液料比20∶1、提取时间2 h的工艺条件下,所得提取物对大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉的抑菌效果最好,抑菌圈直径分别为:9.33、15.67、10.00、6.67 mm,最低抑菌浓度分别为:0.025 00、0.012 50、0.050 00、0.100 00 g·mL−1,竹屑天然防腐剂得率为4.77%。响应面方差分析表明,回归方程拟合程度较高[26],所得最优参数组合具可行性,能较准确模拟竹屑制备天然防腐剂的实际情况。

抑菌试验结果表明,用竹屑制备的天然防腐剂具有较宽的抑菌谱,对大肠杆菌、金黄色葡萄球菌、枯草芽孢杆菌和黑曲霉等4种供试菌均具有不同程度的抑菌作用,但其对真菌的抑菌效果明显弱于细菌,这可能与两类菌结构及生理差异有关。革兰氏阳性菌对制备所得天然防腐剂的敏感度高于革兰氏阴性菌。竹提取物的化学成分主要包括黄酮及其苷类、多糖类、氨基酸及其肽类、芳香成分以及微量元素等[27]。其中,黄酮类化合物对细菌的抑制效果明显,抗菌活性可能与其可与细胞外可溶性蛋白、细胞膜形成复合物,或通过抑制细胞内脱氢酶的活性,从而抑制细菌细胞的新陈代谢有关,许多亲脂类黄酮还可能破坏微生物的细胞膜[28-29]。

天然防腐剂因安全无毒、高效和抗菌范围广等优势,逐步被应用于各食品生产领域[30]。近年来开发的天然防腐剂中,植物提取物类占较大比例,其中以竹原料进行的抑菌研究多集中在竹叶、竹叶挥发油和竹纤维提取物等方面[31-33],这些原料本身仍可为造纸、香料、化妆品和饲料等行业所用,还存在较高的经济价值。本研究以竹产业加工中产生的竹废弃物通过乙酸乙酯回流法进行天然防腐剂的制备,成本低廉且可以变废为宝,提取工艺简单可行。本研究获得了对细菌和真菌等微生物都具备一定抑菌效果的天然防腐剂,可为竹产业加工废弃物的综合利用提供新思路、新途径,有助于减少环境污染,也为天然植物源防腐剂的开发利用提供了依据,但其活性成分及防腐机理还有待进一步研究。

-

表 1 Box-Behnken试验设计的因素及水平

Table 1 Factors and levels of Box-Behnken experimental design

水平

Level提取温度

Extraction temperature/℃液料比

Solvent-to-substrate ratio/(mL:g)提取时间

Extraction time/h−1 80 15∶1 1 0 90 20∶1 2 1 100 25∶1 3 表 2 响应面试验设计组合及结果

Table 2 Design combinations and results of response surface test

试验号

Test numberA提取温度

Extraction temperature/℃B液料比

Solvent-to-substrate ratio/(mL:g)C提取时间

Extraction time/h抑菌圈直径 Inhibitory zone diameter/mm 大肠杆菌

E. coli金黄色葡萄球菌

S. aureus枯草芽孢杆菌

B. subtilis黑曲霉

A. niger平均值

Average1 80 15∶1 2 3.75 6.79 2.50 3.21 4.06 2 100 15∶1 2 2.82 3.42 6.59 4.21 4.26 3 80 25∶1 2 4.24 7.41 5.38 3.58 5.15 4 100 25∶1 2 3.22 2.80 4.80 2.19 3.25 5 80 20∶1 1 3.50 8.56 1.88 2.70 4.16 6 100 20∶1 1 1.20 2.02 2.75 1.26 1.81 7 80 20∶1 3 4.58 8.96 3.02 3.76 5.08 8 100 20∶1 3 3.82 4.41 5.56 3.41 4.30 9 90 15∶1 1 2.52 3.86 4.00 2.42 3.20 10 90 25∶1 1 3.15 4.02 4.22 1.78 3.29 11 90 15∶1 3 5.49 6.54 6.78 3.92 5.68 12 90 25∶1 3 5.86 7.64 8.42 3.60 6.38 13 90 20∶1 2 8.75 16.02 10.51 7.25 10.63 14 90 20∶1 2 9.75 14.03 11.00 7.47 10.56 15 90 20∶1 2 7.75 14.98 10.03 7.01 9.94 16 90 20∶1 2 9.25 15.54 10.35 7.34 10.62 17 90 20∶1 2 9.15 16.40 9.90 7.21 10.67 表 3 响应面方差分析

Table 3 Variance analysis of response surfaces

差异来源

Source平方和

Sun of quares自由度

Degree of freedom均方

Mean squareF值

F valueP值

P value模型 Model 154.75 9 17.19 94.18 <0.000 1** A-提取温度Extraction temperature 2.92 1 2.92 15.97 0.005 2** B-液料比Solvent-to-substrate ratio 0.095 1 0.095 0.52 0.494 9 C-提取时间Extraction time 10.08 1 10.08 55.21 0.000 1** AB 1.1 1 1.1 6.04 0.043 6* AC 0.62 1 0.62 3.38 0.108 8 BC 0.093 1 0.093 0.51 0.498 4 A2 53.12 1 53.12 290.98 <0.000 1** B2 31.89 1 31.89 174.67 <0.000 1** C2 40.32 1 40.32 220.85 <0.000 1** 残差 Residual 1.28 7 0.18 失拟项 Lack of fit 0.9 3 0.3 3.2 0.145 5 纯误差 Pure error 0.38 4 0.094 总和 Total 156.03 16 注:*表示显著差异,P<0.05;**表示极显著差异,P<0.01。

Note: * P<0.05, the difference is significant at 0.05 level; ** P<0.01, the difference is significant at 0.01 level.表 4 最低抑菌浓度的测定

Table 4 Determination of minimal inhibitory concentration for peak antimicrobial effect

抑菌浓度

Concentration /g·mL−1抑菌圈直径 Inhibitory zone diameter/mm 大肠杆菌

E. coli金黄色葡萄球菌

S. aureus枯草芽孢杆菌

B. subtilis黑曲霉

A. niger0.200 00 5.24±0.83 8.06±0.62 7.64±0.85 4.06±0.72 0.100 00 4.38±0.77 6.42±0.81 5.32±0.76 1.04±0.18 0.050 00 2.18±0.22 5.02±0.57 2.14±0.35 0.00 0.025 00 1.15±0.14 3.02±0.42 0.00 0.00 0.012 50 0.00 1.04±0.15 0.00 0.00 0.006 25 0.00 0.00 0.00 0.00 空白对照 Blank control 0.00 0.00 0.00 0.00 -

[1] 吴协保, 吴健, 但新球, 等. 竹类资源在我国石漠化防治中的应用研究 [J]. 世界林业研究, 2015, 28(3):37−41. WU X B, WU J, DAN X Q, et al. Application research of bamboo resources on rockification control in China [J]. World Forestry Research, 2015, 28(3): 37−41.(in Chinese)

[2] 辜夕容, 邓雪梅, 刘颖旎, 等. 竹废弃物的资源化利用研究进展 [J]. 农业工程学报, 2016, 32(1):236−242. DOI: 10.11975/j.issn.1002-6819.2016.01.033 GU X R, DENG X M, LIU Y N, et al. Review on comprehensive utilization of bamboo residues [J]. Transactions of the CSAE, 2016, 32(1): 236−242.(in Chinese) DOI: 10.11975/j.issn.1002-6819.2016.01.033

[3] 李媛媛, 张双燕, 王传贵, 等. 毛竹采伐剩余物的化学成分、纤维形态及纸浆性能 [J]. 浙江农林大学学报, 2019, 36(2):219−226. DOI: 10.11833/j.issn.2095-0756.2019.02.002 LI Y Y, ZHANG S Y, WANG C G, et al. Chemical composition, fiber morphology, and pulping properties of logging residues in Phyllostachys edulis [J]. Journal of Zhejiang A & F University, 2019, 36(2): 219−226.(in Chinese) DOI: 10.11833/j.issn.2095-0756.2019.02.002

[4] 苏秋丽, 蒋剑春, 冯君锋, 等. 竹屑加压液化制备甲基糖苷和酚类物质 [J]. 林产化学与工业, 2017, 37(6):81−88. DOI: 10.3969/j.issn.0253-2417.2017.06.011 SU Q L, JIANG J C, FENG J F, et al. Preparation of methyl glucoside and phenols from pressurized liquefaction of bamboo [J]. Chemistry and Industry of Forest Products, 2017, 37(6): 81−88.(in Chinese) DOI: 10.3969/j.issn.0253-2417.2017.06.011

[5] WANG Y P, DAI L L, FAN L L, et al. Microwave-assisted catalytic fast co-pyrolysis of bamboo sawdust and waste tire for bio-oil production [J]. Journal of Analytical and Applied Pyrolysis, 2017, 123: 224−228. DOI: 10.1016/j.jaap.2016.11.025

[6] 林艳, 房桂干, 邓拥军. 马来酸催化竹屑水解高收率制备戊糖的工艺研究 [J]. 现代化工, 2017, 37(2):95−98. LIN Y, FANG G G, DENG Y J. Preparation of pentose with high yield from bamboo sweeps catalyzed by maleic acid [J]. Modern Chemical Industry, 2017, 37(2): 95−98.(in Chinese)

[7] JIN J W, WANG M Y, CAO Y C, et al. Cumulative effects of bamboo sawdust addition on pyrolysis of sewage sludge: Biochar properties and environmental risk from metals [J]. Bioresource Technology, 2017, 228: 218−226. DOI: 10.1016/j.biortech.2016.12.103

[8] 冯培松, 吕剑明, 徐玮. 竹屑与煤混合制备活性炭的探讨 [J]. 广东化工, 2015, 42(18):70−71. DOI: 10.3969/j.issn.1007-1865.2015.18.033 FENG P S, Lü J M, XU W. Preparation of cativated carbon form the mixture which made of by bamboo sawdust and coal [J]. Guangdong Chemical Industry, 2015, 42(18): 70−71.(in Chinese) DOI: 10.3969/j.issn.1007-1865.2015.18.033

[9] 蒋应梯, 潘炘, 庄晓伟, 等. 竹屑制汽油蒸气吸附和液相脱色的颗粒活性炭研究 [J]. 竹子研究汇刊, 2015, 34(1):54−58. JIANG Y T, PAN X, ZHUANG X W, et al. The preparation of granular activated carbon made of bamboo sawdust as gasoline vapor adsorbent and liquid decolorization [J]. Journal of Bamboo Research, 2015, 34(1): 54−58.(in Chinese)

[10] 张健, 张微思, 龚长久, 等. 竹屑在香菇栽培中的应用 [J]. 中国食用菌, 2016, 35(5):17−20. ZHANG J, ZHANG W S, GONG C J, et al. Application of bamboo chips residues in the cultivation of Lentinula edodes [J]. Edible Fungi of China, 2016, 35(5): 17−20.(in Chinese)

[11] 张雪, 李焱. 不同提取方法对竹屑多糖提取得率影响的研究 [J]. 广州化工, 2018, 46(5):88−90, 110. ZHANG X, LI Y. Study of effects of different extracting methods on extraction rate of polysaccharide from bamboo sawdust [J]. Guangzhou Chemical Industry, 2018, 46(5): 88−90, 110.(in Chinese)

[12] 许子竞, 舒群威, 罗树常. 响应面法优化提取竹屑多糖的工艺研究 [J]. 食品研究与开发, 2017, 38(9):70−73, 117. DOI: 10.3969/j.issn.1005-6521.2017.09.016 XU Z J, SHU Q W, LUO S C. Optimization of the extraction technique of bamboo chip polysaccharide by response surface methodology [J]. Food Research and Development, 2017, 38(9): 70−73, 117.(in Chinese) DOI: 10.3969/j.issn.1005-6521.2017.09.016

[13] 贾燕芳. 竹笋加工废弃物中纤维再生利用研究及产业链设计[D]. 杭州: 浙江大学, 2011. JIA Y F. Research on the utilization of fibers from bamboo shoots processing and recycling industry chain design[D].Hangzhou: Zhejiang University, 2011.(in Chinese)

[14] 陈瑞, 朱圣东, 杨武, 等. 竹子化学成分的测定 [J]. 武汉工程大学学报, 2013, 35(2):57−59, 64. DOI: 10.3969/j.issn.1674-2869.2013.02.012 CHEN R, ZHU S D, YANG W, et al. Analysis of chemical components of bamboo [J]. Journal of Wuhan Institute of Technology, 2013, 35(2): 57−59, 64.(in Chinese) DOI: 10.3969/j.issn.1674-2869.2013.02.012

[15] LEE Y S, LEE Y J, PARK S N. Synergistic antimicrobial effect of Lonicera japonica and Magnolia obovata extracts and potential as a plant-derived natural preservative [J]. Journal of Microbiology and Biotechnology, 2018, 28(11): 1814−1822. DOI: 10.4014/jmb.1807.07042

[16] CALEJA C, BARROS L, PRIETO M A, et al. Development of a natural preservative obtained from male chestnut flowers: optimization of a heat-assisted extraction technique [J]. Food & Function, 2019, 10(3): 1352−1363.

[17] KALEM I K, BHAT Z F, KUMAR S, et al. Preservative potential of Tinospora cordifolia, a novel natural ingredient for improved lipid oxidative stability and storage quality of chevon sausages [J]. Nutrition & Food Science, 2018, 48(4): 605−620.

[18] 曹小燕, 杨海涛. 响应面法优化超声辅助提取荠菜多酚工艺及其抗氧活性研究 [J]. 食品工业科技, 2019, 40(2):223−228, 232. CAO X Y, YANG H T. Optimization of ultrasonic assisted extraction technology of polyphenol by response surface methodology from Capsella bursa-pastoris and its antioxidant activity [J]. Science and Technology of Food Industry, 2019, 40(2): 223−228, 232.(in Chinese)

[19] 滕蓉. 鬼针草提取物抑菌及抗氧化活性研究[D]. 福州: 福建农林大学, 2013. TENG R. Study on antimicrobial and antioxidant activity of Bidens bipinnata extracts[D]. Fuzhou: Fujian Agriculture and Forestry University, 2013.(in Chinese)

[20] 倪向梅. 从竹叶中提取化妆品用防腐剂的研究[D]. 无锡: 江南大学, 2011. NI X M. The research on extracting cosmetics preservative from bamboo leaves[D]. Wuxi, China: Jiangnan University, 2011.(in Chinese)

[21] 杨立芳, 刘洪存, 支媛, 等. 响应曲面法优化毛果鱼藤总生物碱的提取工艺及其抑菌活性 [J]. 中国实验方剂学杂志, 2016, 22(23):28−34. YANG L F, LIU H C, ZHI Y, et al. Optimization of extraction process and antibacterial activity of total alkaloids from Derris eriocarpa based on response surface method [J]. Chinese Journal of Experimental Traditional Medical Formulae, 2016, 22(23): 28−34.(in Chinese)

[22] 陈佳丽, 王可, 赵敏, 等. 香辛料对烧鸡中腐败菌抑制效果的研究 [J]. 肉类工业, 2018(10):28−32. DOI: 10.3969/j.issn.1008-5467.2018.10.008 CHEN J L, WANG K, ZHAO M, et al. Study on the inhibitory effect of spice on spoilage bacteria in roast chicken [J]. Meat Industry, 2018(10): 28−32.(in Chinese) DOI: 10.3969/j.issn.1008-5467.2018.10.008

[23] 田凤, 李晓, 崔宇倩, 等. 香辛料提取液对假单胞菌和葡萄球菌及热死环丝菌的抑菌研究 [J]. 北京农学院学报, 2017, 32(2):10−14. TIAN F, LI X, CUI Y Q, et al. Study on antibacterial activity of 7 spices on Pseudomonas, Staphylococcus and Brochothrix [J]. Journal of Beijing University of Agriculture, 2017, 32(2): 10−14.(in Chinese)

[24] 郑思睿, 杨婷, 依木然·马瑞士, 等. 响应面法优化罗布麻多糖提取工艺及抗氧化活性研究 [J]. 食品研究与开发, 2018, 39(16):93−97. DOI: 10.3969/j.issn.1005-6521.2018.16.017 ZHENG S R, YANG T, Emran Maris, et al. Study on extraction and antioxidant activity of polysaccharides in Apocynum venetum by response surface methods [J]. Food Research and Development, 2018, 39(16): 93−97.(in Chinese) DOI: 10.3969/j.issn.1005-6521.2018.16.017

[25] 赵强, 余四九, 王廷璞, 等. 响应面法优化秃疮花中生物碱提取工艺及抑菌活性研究 [J]. 草业学报, 2012, 21(4):206−214. DOI: 10.11686/cyxb20120425 ZHAO Q, YU S J, WANG T P, et al. Optimization of the extracting process for alkaloids from Dicranostigma leptopodum by response surface analysis and study on its antibacterial activity in vitro [J]. Acta Prataculturae Sinica, 2012, 21(4): 206−214.(in Chinese) DOI: 10.11686/cyxb20120425

[26] 张彬, 谢明勇, 殷军艺, 等. 响应面分析法优化超声提取茶多糖工艺的研究 [J]. 食品科学, 2008, 29(9):234−238. DOI: 10.3321/j.issn:1002-6630.2008.09.050 ZHANG B, XIE M Y, YIN J Y, et al. Optimization of ultrasonic-assisted extraction conditions of tea polysaccharides by using response surface methodology [J]. Food Science, 2008, 29(9): 234−238.(in Chinese) DOI: 10.3321/j.issn:1002-6630.2008.09.050

[27] 赖炘, 陈其兵. 竹叶提取物的化学成分及其生理功能研究进展 [J]. 福建林业科技, 2013, 40(1):214−220, 226. DOI: 10.3969/j.issn.1002-7351.2013.01.48 LAI X, CHEN Q B. The research progress of chemical composition and physiological function of extract of bamboo leaves [J]. Journal of Fujian Forestry Science and Technology, 2013, 40(1): 214−220, 226.(in Chinese) DOI: 10.3969/j.issn.1002-7351.2013.01.48

[28] TSUCHIYA H, SATO M, MIYAZAKI T, et al. Comparative study on the antibacterial activity of phytochemical flavanones against methicillin-resistant Staphylococcus aureus [J]. Journal of Ethnopharmacology, 1996, 50(1): 27−34. DOI: 10.1016/0378-8741(96)85514-0

[29] 曾春晖, 杨柯, 徐明光, 等. 广西藤茶总黄酮对金黄色葡萄球菌抗菌机制研究 [J]. 中国实验方剂学杂志, 2013, 19(10):249−252. ZENG C H, YANG K, XU M G, et al. Antibacterial mechanisms of total flavonoids from Ampelopsis grossedentata on Staphylococcus aureus [J]. Chinese Journal of Experimental Traditional Medical Formulae, 2013, 19(10): 249−252.(in Chinese)

[30] 范超, 张梅, 张晶. 天然防腐剂的研究进展 [J]. 食品工业, 2017, 38(10):200−203. FAN C, ZHANG M, ZHANG J. The research progress of natural preservatives [J]. The Food Industry, 2017, 38(10): 200−203.(in Chinese)

[31] 梁倩, 刘蔚漪, 王芳, 等. 野龙竹竹叶中多酚含量及其抑菌活性 [J]. 林业科技开发, 2013, 27(3):112−114. DOI: 10.3969/j.issn.1000-8101.2013.03.030 LIANG Q, LIU W Y, WANG F, et al. A study on polyphenol content and antibacterial activities in leaves of Dendrocalamus semiscandens [J]. China Forestry Science and Technology, 2013, 27(3): 112−114.(in Chinese) DOI: 10.3969/j.issn.1000-8101.2013.03.030

[32] 杨萍, 刘洪波, 潘佳佳, 等. 不同季节毛竹竹叶挥发油成分与抑菌效果比较研究 [J]. 核农学报, 2015, 29(2):313−320. DOI: 10.11869/j.issn.100-8551.2015.02.0313 YANG P, LIU H B, PAN J J, et al. Analysis of the components in leaves of Phyllostachys edulis harvested in four seasons and the anti-microbial effects of their essential oils [J]. Journal of Nuclear Agricultural Sciences, 2015, 29(2): 313−320.(in Chinese) DOI: 10.11869/j.issn.100-8551.2015.02.0313

[33] 阮祥春, 黄媛媛, 赵德学, 等. 竹纤维提取物体外抗菌活性及提取方法的研究 [J]. 西北农林科技大学学报(自然科学版), 2015, 43(11):134−138. RUAN X C, HUANG Y Y, ZHAO D X, et al. Extraction methods and in vitro antibacterial activity of bamboo(Phyllostachys pubescens) fiber extracts [J]. Journal of Northwest A & F University(Natural Science Edition), 2015, 43(11): 134−138.(in Chinese)

-

期刊类型引用(2)

1. 刘强,韩卿,陈卓,庄堃,罗建雄. 生物酶法竹渣填料的制备及其抄纸应用性能研究. 中国造纸. 2022(08): 82-89 .  百度学术

百度学术

2. 杨波,益莎,施锴芸,李琴,杨光,贺亮. 竹笋加工剩余物中笋篼黄酮提取、结构鉴定及生物活性研究. 食品与发酵工业. 2021(11): 208-215 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: