Physicochemical Properties of Tomato Vine Biochar Prepared by Different Pyrolytic Temperatures

-

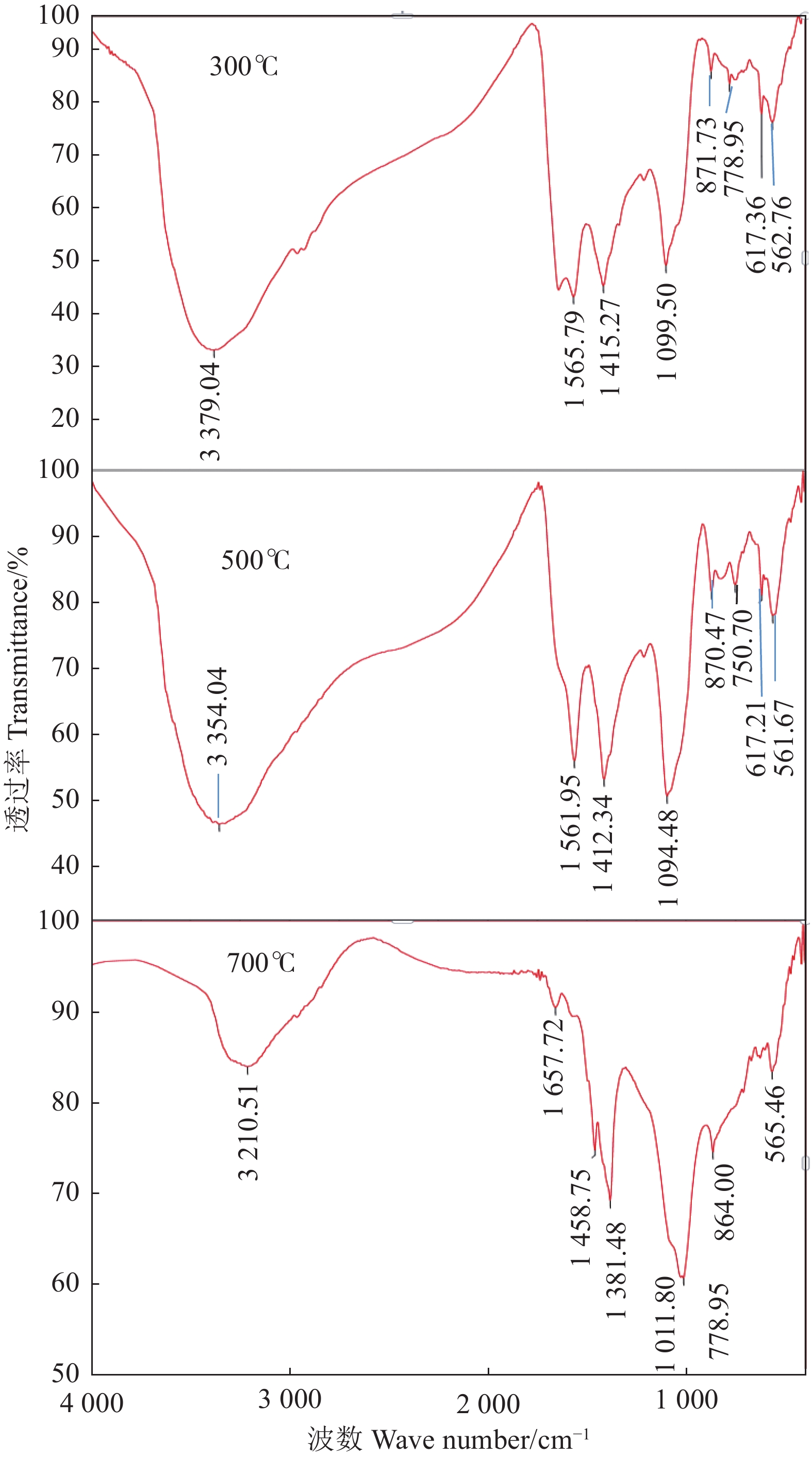

摘要:目的 探究裂解温度对番茄藤蔓生物炭理化特性的影响。方法 300 ℃、500 ℃ 和 700 ℃下热解2 h制备生物炭,运用电镜扫描、元素分析仪和傅里叶变换红外光谱分析仪等手段,对番茄藤蔓生物炭的表面结构特征、元素及其他特性、表面官能团等进行综合分析。结果 裂解法制备的番茄藤蔓生物炭呈碱性(pH值9.83~10.67),生物炭产率随裂解温度的升高而降低,灰分则相反。全氮含量以500 ℃时最低,300 ℃时最高,但固定碳含量、碳氮比(C/N比)均在500 ℃时含量相对较高,分别为51.42%和36.63。低温裂解时番茄藤蔓生物炭孔隙结构丰富,高温下裂解其孔隙被灰分及其熔融结构覆盖,孔隙度减小。热解温度的升高同时使生物炭芳香化程度增强,700 ℃高温热解时的傅里叶红外光谱图相较于300 ℃和500 ℃谱图吸收峰减少,尤其在500~800 cm−1的吸收峰明显减弱。结论 热裂解改变了番茄藤蔓生物炭的理化特性和微观结构,综合考虑各因素,300~500 ℃下裂解2 h制备的番茄生物炭具有较好的性能和较高的效益。Abstract:Objective Effect of processing temperature in pyrolysis of discarded tomato vines on the physiochemical properties of the resulting biochar was studied.Methods Biochar of waste tomato vines were prepared under the pyrolytic temperatures of 300 ℃, 500 ℃, and 700 ℃ for 2h. Surface characteristics, element, and functional groups of the biochar were examined by means of electron microscope scanning, elemental analysis, and Fourier transform infrared spectrometer.Results The biochar prepared under different pyrolytic temperatures had a pH ranging 9.83-10.67. High process temperature reduced the yield but increased the ash content of the biochar. At 500 ℃, the biochar had the least amount of total nitrogen, but the highest at 300 ℃. At 500 ℃, the fixed carbon content peaked at 51.42%, and the C/N ratio at 36.63. More pores appeared on the biochar made by a lower than a higher temperature, under which ash and/or molten elements tended to cover the surface reducing the porosity. A high pyrolytic temperature, comparing 700 ℃ to 300 ℃ or 500 ℃, also raised the aromatization, as shown by the declined Fourier transform infrared spectroscopy spectrum absorption, especially at 500-800cm−1 region.Conclusion The temperature applied in pyrolysis affected the physics, chemistry, and microstructure of the tomato vine biochar. Overall, a pyrolysis process of 300-500 ℃ for 2 h appeared to deliver desirable results.

-

Keywords:

- Biochar /

- tomato vine /

- pyrolysis temperature /

- surface structure

-

0. 引言

【研究意义】作为三大世界性贸易蔬菜之一,番茄在全球蔬菜贸易中占有重要地位[1]。而且随着需求量的不断上升,世界番茄生产总量及种植规模不断扩大。1994年全球番茄种植面积为316万hm2[2],2020年上升至505.5万hm2。近年来我国番茄栽培面积也一直处于稳中有升态势,据统计,2020年我国番茄种植面积为110.4万hm2,同比增长1.6%,2021年约为111.3万hm2,同比增长0.77%。随着番茄种植规模的持续增长,我国番茄产量也在稳定上升,2020年约达6515万t,同比增长3.63%,2021年约为6609万t,同比增长1.44%。目前已是全球番茄第一大国,常年产量占全球的1/3甚至以上[3]。按照蔬菜平均产废系数0.36[4,5]来计算,2021年我国番茄藤蔓废弃物理论数量为2.4×107 t。作为蔬菜废弃物的第一大秸秆资源,番茄藤蔓废弃物数量巨大,但又难以像其他农作物秸秆一样直接还田。按照习惯,对其废弃物基本就是乱堆乱放、一弃了之,大多数达不到及时有效的利用和处理,不仅是病虫害的重要传播源,而且易引起环境污染等问题。如何资源化利用番茄藤蔓,一直是番茄产业及种植户亟待解决的突出问题。【前人研究进展】据研究[5,6],番茄藤蔓的碳氮比(C/N)为28.34,有机质含量为 53.49%,木质素含量为5.24%,纤维素含量为22.19%,半纤维素含量为 7.60%,粗蛋白含量为 13.46%,N、P和K总养分含量为4.07%~7.65%,可见其养分含量丰富,是非常可观的碳源资源。近年来,随着绿色农业、生态农业、循环农业等概念和相关政策的提出,秸秆资源化利用技术不断得到发展完善。就目前国内外的研究来看,对番茄藤蔓的资源化利用大多集中在秸秆还田、堆肥处理、饲料、基料、沼气等[7−11]方面,从结果来看,由于番茄藤蔓的木质化程度高,自然分解速度较慢,所以秸秆还田对秸秆的利用率非常低,不论是肥料化、基料化还是饲料化,均难以达到预期效果,需要额外添加和配比其他的微生物或者污泥等物质来提升效果。生物炭化利用是秸秆资源化利用的一个新方向和研究热点,是秸秆农用十大模式之一[12,13]。秸秆生物炭是指将秸秆残体在厌氧或缺氧的条件下,通过高温加热生产出来的一类富含碳素、稳定、难熔、高度芳香化的固态物质[14,15]。生物炭的合理利用对农业生产来讲意义重大,它的利用有利于减少秸秆焚烧,有利于减少化肥的施用,有利于减少生产中的碳排放。近年来,国内外很多学者在秸秆生物炭的制备、性质及其在农业和生态环境领域的应用等方面进行了大量的研究[16−22]。研究发现,生物炭的理化性质决定其在土壤中的效应,其性质不仅与炭化工艺有着密切的联系,而且受生物炭原材料的影响较大,通过对玉米、水稻、小麦、油菜等的秸秆生物炭的研究发现[23−28],秸秆原料不同,制备工艺(例如裂解加热方式、裂解温度、裂解时间及升温程序等)不同,所制备的生物炭的性质及表征也有所差异,直接影响到后期生物炭的综合利用[29]。【本研究切入点】目前对番茄藤蔓生物炭的研究还鲜有报道,不同裂解温度对番茄藤蔓生物炭理化性质的影响机制有待深入研究。【拟解决的关键问题】本研究以番茄藤蔓为原料,用热裂解的方法制备番茄藤蔓生物炭,通过调整不同的裂解温度,采用元素分析、傅立叶红外光谱以及扫描电镜分析技术,分析不同裂解温度下番茄藤蔓生物炭的产率、pH值、EC值、灰分、挥发分、C/N等的变化,以及功能基团和表面的微观结构的不同表征,旨在为干热裂解方法制备番茄藤蔓生物炭提供技术参考,也为番茄藤蔓资源化循环利用和后期应用提供理论借鉴。

1. 材料与方法

1.1 试验材料

以番茄藤蔓为试验材料,来源于福建某企业采果后的废弃物。以去离子水洗去表面的灰尘和泥土,剪成约2 cm长的小段,自然风干后放烘箱中105 ℃烘干至恒重。

1.2 生物炭的制备

称取一定量的烘干番茄藤蔓,将其放入马弗炉(Box resistance furnace,BSX2-5-12TP,上海一恒科学仪器有限公司)中,通入氮气形成厌氧环境,2 min后开始加热升温到裂解温度300 ℃、500 ℃和700 ℃,热解停留时间均为2 h。裂解反应结束后,待生物炭冷却至室温后及时收取,密封保存备用。

1.3 生物炭相关理化指标测定

1.3.1 产率测定

烘干番茄藤蔓称重(初始干物质重量),置于坩埚中,于马弗炉中热裂解,裂解结束后冷却至室温后取出称量(反应后干物质重量),前后质量比即为产率。即生物炭产率/%=(反应后干物质重量/初始干物质重量)×100。

1.3.2 灰分含量的测定

参照GB/T 17664—1999《木炭和木炭的实验方法》进行测定。将陶瓷坩埚于650 ℃灼烧至恒重,取出坩埚,放在干燥器里干燥冷却30 min,取出称重,记为G1。然后将生物炭粉碎,称取2~3 g (精确至0.0001),放入坩埚中,分别做2~3个平行,称重记为G2,马弗炉设置温度300 ℃,维持30 min,温度升高至500 ℃,维持30 min,温度升至800 ℃,维持7 h,待自然冷却,取出坩埚,放至干燥器中冷却30 min,称重记为G3。 然后根据公式:灰分/%= [(G3−G1) /(G2−G1)] ×100,计算灰分含量。

1.3.3 挥发分含量的测定

参照GB/T 2001—2013《焦炭工业分析测定方法 挥发分含量的测定》进行测定。准确称取1 g(精确至0.0001) 生物炭记为G1,放入用预先灼烧至恒重(记为G2)的带盖瓷坩埚,盖上盖。马弗炉预先升温至890 ~910 ℃,将瓷坩埚迅速送入马弗炉中,关好炉门,计时7 min,从炉中迅速取出瓷坩埚,常温条件下冷却约5 min,再移入干燥器中继续冷却约30 min,称量记为G3。然后根据公式:挥发分/%= [G1−(G3−G2)]/G1×100,计算挥发分含量。

1.3.4 固定碳含量

固定碳指在高温下有效的碳素百分含量。固定碳以经干燥后的木炭质量,减去其所含灰分及挥发分来计算,计算公式:固定碳含量/%=100−灰分(%)−挥发分(%)。

1.3.5 有机碳含量的测定

参考农业行业标准NY/T 3672—2020 [30]。

1.3.6 全氮含量测定

采用凯氏定氮法[31]测定。

1.3.7 pH值和电导率(EC)

pH值和电导率的测定 参考 GB /T 12496.7—1999 《木质活性炭试验方法 pH值的测定》进行测定。称取 1.00 g(称确至0.01 g)生物炭放入50 mL锥形瓶中,加入无 CO2蒸馏水20 mL,加热,缓和煮沸5 min,补添蒸发的水,过滤,弃去初滤液5 mL。余液冷却至室温后用pH计测定,并记录读数。之后用滤纸过滤,用电导仪测定滤液的EC值。

1.4 生物炭扫描电镜观察

选取部位一致的材料,吹去其表面的细微粉末,将其黏在粘有导电胶的铜台上,经离子溅射仪(EIKO)喷金镀覆,处理好的样品在扫描电镜(JEOL JSM-6380LV)下观察。

1.5 生物炭功能基团分析

番茄藤蔓生物炭用玛瑙研钵碾磨成粉末,然后将生物炭和KBr以1∶100的比例混合压片后测定。采用傅立叶变换红外光谱仪(Nicolet iS50 FT-IR,Thermo Fisher Scientific,USA)在400~4000 cm−1波数范围内扫描形成图谱。FTIR测试结果由Omnic V8.20软件进行处理。结果分析参考翁诗甫等[32]的方法进行。

1.6 数据处理

产率、灰分等特征参数数据使用 IBM SPSS Statistics 27 软件结合Microsoft Excel 2010进行单因素方差分析,采用Tukey 多重比较法比较不同处理间的差异性,结果采用平均值±标准差表示,显著性水平定为 P<0.05。

2. 结果与分析

2.1 不同热解温度下生物炭产率、灰分和挥发分的变化

不同热解温度下番茄藤蔓生物炭产率如表1所示,300 ℃、500 ℃及700 ℃下热解2 h,生物炭产率分别为46.19%、34.11%、29.00%,随着热解温度的升高生物炭产率显著降低(P<0.05)。到500 ℃时生物炭产率迅速下降12.08%,700 ℃灰分含量分别为18.37%、21.53%、27.58%,随热解温度的升高番茄藤蔓生物炭灰分比例不断增加,而且各处理间差异显著(P<0.05)。挥发分含量为27.05%~36.68%,由表1可见,随着热解温度的升高挥发分含量呈减少的趋势,300 ℃时挥发分含量最高,到500 ℃时显著下降 (P < 0.05),700 ℃与500 ℃相比差异不显著。

表 1 不同热解温度下番茄藤蔓生物炭的产率和理化性质Table 1. Productivity and physicochemical properties of tomato vine biochar prepared under different pyrolytic temperatures产率和理化性质

Productivity and physicochemical properties热解温度 Pyrolytic temperature 300 ℃ 500 ℃ 700 ℃ 产率 Productivity/% 46.19±0.26 a 34.11±0.95 b 29.00±0.10 c 灰分 Ash content/% 18.37±0.86 c 21.53±0.62 b 27.58±0.61 a 挥发分 Volatile/% 36.68±0.98 a 27.05±2.33 b 27.87±0.57 b pH值 pH value 9.83±0.07 c 10.67±0.03 a 10.03±0.06 b 电导率 Electrical conductivity/(µS·cm−1) 11.02±0.04 c 11.90±0.06 a 11.48±0.05 b 全氮 Total nitrogen/% 1.91±0.01 a 1.63±0.01 c 1.85±0.01 b 固定碳 Fixed carbon/% 44.94±1.33 b 51.42±2.81 a 44.54±1.03 b 有机碳 Organic carbon/% 59.94±0.34 a 59.71±0.39 a 56.51±0.00 b C/N 31.38±0.05 b 36.63±0.23 a 30.57±0.19 c 同行数字后不同小写字母表示不同处理之间差异显著(P<0.05)。

Data with different lowercase letters on the same row indicate significant differences (P<0.05).2.2 不同热解温度下生物炭pH、EC的变化

由表1可知,在300 ~700 ℃热解温度下,番茄藤蔓制备的生物炭呈碱性。随着热解温度的升高,pH呈现先增加后减小的趋势,热解温度为300 ℃时,番茄藤蔓生物质炭 pH为9.83,500 ℃时明显增加至10.67,700 ℃时pH值减小为10.03。EC值可以指示生物炭中所含的水溶性离子的情况,是生物炭含盐量的一个综合性指标。本研究中,生物炭EC值介于11.02~11.90 µS·cm−1 ,均值为11.47 µS·cm−1,EC值比较小,随着热解温度的增加,番茄藤蔓生物炭EC值先增加后减小,处理间差异显著(P<0.05)。

2.3 不同热解温度下生物炭总有机碳、氮、固定碳含量及C/N的变化

由表1可知,随热解温度的升高,番茄藤蔓生物炭全氮含量先下降后上升,在500 ℃和700 ℃时含量较低,分别为1.63%和1.85%,300 ℃时含氮量相对较高,为1.91%,方差分析结果表明,各处理间差异显著(P<0.05)。固定碳含量则随热解温度的增加,先增加后减少,500 ℃时其含量显著增加,为51.42%。300 ℃、500 ℃和700 ℃时有机碳的含量分别为59.94%、59.71%和56.51%,300 ℃和500 ℃处理间差异不显著,700 ℃时显著降低。本试验中, 生物炭的C/N范围为30.57~36.63,随热解温度升高C/N先增加后减小,500 ℃下热解2 h时其生物炭C/N最高,且各处理间差异显著。

2.4 不同热解温度下番茄生物炭表面形态的变化

由图1 可见,在不同热解温度下制备的番茄生物炭的结构差别较大。由图1-a, b, c可知,番茄藤蔓原料干样时,番茄藤蔓皮层可见直立的绒毛,还有气孔结构,横切面可见番茄藤蔓由外到内的结构为表皮组织、维管束组织和一些基本的薄壁组织,茎秆中部髓部呈中空状(含少量维管束)。维管束呈多空和管状结构,并可见环纹导管及网纹导管,薄壁细胞的厚度约为1.51~2.12 μm,之间 充斥着薄壁组织,在横切面上近似于圆形或呈多角形,在薄壁组织上有纹孔并可见一些三角锥形或圆形的淀粉颗粒。热解温度为300 ℃时(图1-d, e, f),番茄藤蔓生物炭的基本组织完整,维管束鞘结构清晰,环状导管结构清晰,环状导管的表面可见颗粒物质存在,薄壁细胞的纹孔也清晰可见,薄壁细胞厚度约为1.29~1.66 μm,而且薄壁细胞表面可见绒毛状的炭化结构,细胞表面淀粉粒有的呈六面体结构。热解温度为500 ℃时(图1-g, h, i),番茄藤蔓生物炭表面可见针状凸起,薄壁细胞表面可见比较粗糙了一点,厚度约为0.95~1.98 μm,绒毛状的炭化结构也清晰可见,表面可见许多的突起状小颗粒,纹孔结构也清晰可见,薄壁组织由不同程度的损伤,可见四面体及六面体的淀粉颗粒结构,这些颗粒或是镶嵌在一种糊状物质当中,髓部可见呈丝状的物质。热解温度为700 ℃时(图1-j, k, l),番茄藤蔓生物炭表面糊化严重,薄壁组织厚度增加,约为3.10~3.97 μm,其上的纹孔也几乎被遮住,维管束横切面及表面沾满了因炭化而破碎的结晶物质颗粒,此外也可发现生物炭颗粒发生了熔融,生物炭表面变得平滑。薄壁组织脆化也比较严重,髓部也填满颗粒状结晶物质。

2.5 不同热解温度对番茄生物炭表面官能团的影响

为了进一步确定不同热解温度对番茄藤蔓生物炭理化性质的影响,对其官能团进行了测定,其傅里叶红外光谱的结果如图2所示。从图2可以看出,在500~4000 cm−1的波数范围内,热解得到的番茄藤蔓生物炭有10~12处明显的吸收峰,其表面官能团结构丰富。综合特征频率区(1330~ 4000 cm−1)以及指纹区(400~1330 cm−1)的光谱图情况,300 ℃和500 ℃下热解所制得的番茄藤蔓生物炭含有的官能团种类相似,说明它们所包含的官能团类型基本相同,700 ℃热解时,谱图相较于300 ℃和500 ℃官能团有所减少,尤其在500~800 cm−1的吸收峰明显减弱。具体来讲,3个热裂解温度下,在3200~3500 cm−1 的区域内吸收峰均存在明显的宽峰值,此段主要对应氢键缔合的-OH基团的伸缩振动,这部分羟基主要为碳水化合物(纤维素、半纤维素、淀粉及其他多糖和单糖等)[33],随着热解温度的升高,该振动吸收有减弱的趋势;1660 cm−1附近的吸收峰对应羧酸类及其酯类等化合物中羰基C=O的伸缩振动,由图2可知,此峰只在700 ℃时出现;1562~1567 cm−1的吸收峰对应羧基振动峰, 随着热解温度的升高,该振动吸收有减弱的趋势;1458 cm−1处的吸收峰对应芳环的骨架振动,只在700 ℃的高温下有这个峰的出现;1381~1416 cm−1 附近的吸收峰对应羧酸根O=C=O的对称伸缩振动,随着热解温度的升高,该振动吸收有减弱的趋势;在指纹区,1011~1099 cm−1的吸收峰对应酚类和氢氧基团中的C-O伸缩振动,随着热解温度的升高,该振动吸收减弱。指纹区内在870 cm−1左右的吸收峰对应芳香族化合物,随热解温度的升高,该振动吸收增强;700~800 cm−1的吸收峰对应芳烃的C-H面弯曲振动,随热解温度的升高,该振动吸收变得平缓;560~700 cm−1的吸收峰对应脂肪族酰卤基团O=C−X 的变角振动吸收,该振动吸收在700 ℃明显变弱。

3. 讨论

3.1 热裂解温度影响番茄藤蔓生物炭的理化性质

热解是一个包含脱水、裂解和炭化的复杂热化学过程,研究表明,生物炭的特性受原材料及裂解工艺的影响,其中温度是主要因素之一。生物炭的组成元素主要为碳、氢、氧等,而且以高度富含碳为主要标志[34]。研究表明,生物炭的pH、有机碳、全氮、灰分和挥发分含量等与裂解温度密切相关。徐亮等[35]对水稻秸秆的研究发现,热解温度低于300 ℃时制成的生物炭呈弱酸性,400 ℃以上时呈碱性,并且随热解温度的升高,水稻秸秆生物炭的产率逐渐降低。本试验中,通过300 ℃、500 ℃和700 ℃ 3种温度下分别裂解2 h,番茄藤蔓生物炭的产率为29.00%~46.19%,且热裂解温度越高,生物炭产率越小,在300~500 ℃时,随裂解温度升高生物炭产率急速下降,主要原因在于在较低温度时生物质中的纤维素和半纤维素等开始分解,这个时候会导致生物炭产率的急速下降[36]。而当温度达到 500 ℃,这两种成分基本热解完全,此时产率虽有下降,但下降趋势有所缓和。pH范围为9.83~10.67,呈碱性,随裂解温度的升高,500 ℃时pH先增加,这是因为在裂解过程中,有机质经过脱水脱羟基等反应析出酸性物质[37],并随着裂解温度的升高,酸性物质的挥发逐渐增多,pH呈上升趋势。700 ℃时,pH减小,说明番茄藤蔓在500 ℃左右其酸性官能团的分解或者有机酸的挥发已经很充分。灰分是生物炭的无机物含量指标,对其性能有显著影响,在农田重金属污染修复过程中具有重要意义[38]。本试验中,灰分含量随热解温度的升高比例增加,挥发分则有减小的趋势,这是因为番茄藤蔓中不同物质的热分解温度并不相同,随裂解温度的升高,生物炭炭化程度增加,灰分含量也相应增加,挥发分物质加快挥发,其含量也相应减小。生物炭中的碳元素,主要是固定碳和一定含量的有机碳。生物炭中的N素,主要以C-N杂环结构存在于生物炭表面,有效氮素含量很低。生物炭通常含碳40%~75%,施入土壤能够提高土壤的有机碳含量。黄康[39]研究发现,相对低温制备的生物炭,高温生物炭施用对土壤总碳和总有机碳的提升效果更加明显,同时还发现还田生物炭温度越高,土壤CO2排放越少。本试验发现,500 ℃下制备的番茄藤蔓生物炭具有较高的固定碳含量和C/N,其应用后对土壤有机碳的提升可能具有更好的效果。

3.2 热解温度影响番茄藤蔓生物炭表面微观结构

生物质经过热解炭化过程可形成孔隙发达、芳香化程度高的富碳微孔结构,施入土壤后可以改善土壤结构,同时对重金属具有良好的固持作用[40]。不同生物质的组织结构、内含物及纤维素、半纤维素以及木质素(三素)含量等不同,制备的生物炭结构差异显著。本试验中,番茄藤蔓原材料从其表观表现来看是制备生物炭的理想材料。不同热解温度下,番茄藤蔓生物炭表面炭化程度不同,但均具有管状和多孔的结构。与原材料相比,300 ℃下生物炭基本组织完整,维管束鞘结构清晰,环状导管结构清晰,环状导管的表面可见颗粒物质存在,薄壁细胞的纹孔也清晰可见。温度升至 500 ℃时,生物炭表面可见针状凸起,薄壁细胞表面相对比较粗糙,纹孔结构仍清晰可见,薄壁组织有不同程度的损伤。当温度达到 700 ℃ 时,生物炭表面糊化严重,薄壁组织厚度增加,其上的纹孔也几乎被遮住。可见在300~500 ℃时,生物炭微孔结构发育较好,这可能是随着热解温度的升高,产生的挥发性气体的释放导致生物炭表面孔隙的张开,形成丰富的微孔结构[41]。700 ℃ 时孔壁变厚,孔隙数量相对减少,其孔隙结构呈不规则状。从研究结果可知,随着温度的升高,生物质会分解为挥发性气体逃逸,使生物炭的孔隙缩小,开孔增多,从而产生更多的微孔结构,导致比面积增大,但是随热解温度的升高番茄藤蔓生物炭孔隙反而减小。这可能是因为高温条件下产生大量糊状物质,不仅平铺在生物炭的表面,而且填充了部分生物炭孔隙,导致其孔隙数量相对减少。此外生物炭在热解过程中受热分解而产生的焦油、灰分等产物也会填充生物炭的内部孔隙结构。

3.3 热解温度影响番茄藤蔓生物炭的官能基团

秸秆多由纤维素和木质素组成,官能团类型众多,一般具有脂肪性和芳香性,经一定温度的热解炭化后,生物质原有结构经过失水、活性物质挥发、断裂、崩塌等一系列重构形成生物炭。 生物炭表面及内部形成大量酸性及碱性官能团, 其中大多为含氧官能团或碱性官能团, 酸性表面官能团有羰基、羧基、内酯基、羟基等,可促进活性炭对碱性物质的吸附;碱性表面官能团主要有吡喃酮(环酮)及其衍生物,可促进活性炭对酸性物质的吸附[42]。这些基团的存在使生物炭具有良好的吸附、亲水或疏水,以及缓冲酸碱、促进离子交换等特性[43]。本试验中,300 ℃和500 ℃温度下热解所制得的番茄藤蔓生物炭含有的官能团种类相似,说明它们所包含的官能团类型基本相同,700 ℃热解条件下,谱图相较于300 ℃和500 ℃吸收峰减少,说明番茄生物炭中的官能团有所减少,尤其在500~800 cm−1的吸收峰明显减弱,说明相比于700 ℃热解,300 ℃和500 ℃热解具备更高的吸附容量。此外,随裂解温度的升高,番茄藤蔓生物炭-OH( 3200~3500 cm−1) 、C=O ( 1600 cm−1附近) 的伸缩振动峰减弱,这可能是由于高温裂解致使番茄藤蔓的-OH 和其他基团发生缩合或脱落所致。本试验中,当炭化温度升高至500 ℃时,芳香化C-H面外弯曲振动(870 cm−1左右)越来越明显,说明随着炭化温度的升高番茄藤蔓炭化脱氢反应加剧,其生物炭芳香化结构增强,高温裂解时其芳香化程度加剧的又一个表现就是当炭化温度达到700 ℃时,芳香化C=C骨架振动(1458 cm−1)也增强,而其他吸收峰的强度均有明显的减弱,这些结果表明,随热裂解温度的增加,番茄藤蔓生物炭的芳香性增强但官能团类型减少。张昌天等[44]的研究表明,随着裂解温度的提高,纤维素和半纤维素的大量分解导致生物炭的官能团类型改变、芳香性增强以及亲水性和极性降低等,从而影响了生物炭颗粒与土壤团聚体的结合程度。一般认为随着炭化温度升高,生物炭芳香化程度的加深,使它具有更高的化学和生物学稳定性,施用土壤后可起到良好的“碳封存”效应,但当超过800 ℃以上时生物炭的碳架结构则出现不稳定现象[45]。可见,裂解温度是影响生物炭性质的关键因子,应针对不同的应用目标选择适宜的裂解温度以获得相应的生物炭材料。

4. 结论

裂解法制备的番茄藤蔓生物炭呈碱性,生物炭产率随裂解温度的升高而减少,灰分则相反。低温裂解(300~500 ℃)下番茄藤蔓生物炭孔隙结构丰富,高温下裂解其孔隙被灰分及其熔融结构覆盖,孔隙度减小。固定碳含量、有机碳含量、C/N、EC值也在低温裂解时含量相对较高。随热解温度的升高生物炭芳香化程度增强。300 ℃和500 ℃下热解制得的番茄藤蔓生物炭含有的官能团种类相似,700 ℃番茄生物炭中的官能团有所减少,尤其在500~800 cm−1的吸收峰明显减弱,相比于700 ℃热解条件,300 ℃和500 ℃热解具备更高的吸附容量。综合考虑各因素,本试验中,300~500 ℃下裂解2 h制备的番茄藤蔓生物炭具有较好的性能与效益。

-

表 1 不同热解温度下番茄藤蔓生物炭的产率和理化性质

Table 1 Productivity and physicochemical properties of tomato vine biochar prepared under different pyrolytic temperatures

产率和理化性质

Productivity and physicochemical properties热解温度 Pyrolytic temperature 300 ℃ 500 ℃ 700 ℃ 产率 Productivity/% 46.19±0.26 a 34.11±0.95 b 29.00±0.10 c 灰分 Ash content/% 18.37±0.86 c 21.53±0.62 b 27.58±0.61 a 挥发分 Volatile/% 36.68±0.98 a 27.05±2.33 b 27.87±0.57 b pH值 pH value 9.83±0.07 c 10.67±0.03 a 10.03±0.06 b 电导率 Electrical conductivity/(µS·cm−1) 11.02±0.04 c 11.90±0.06 a 11.48±0.05 b 全氮 Total nitrogen/% 1.91±0.01 a 1.63±0.01 c 1.85±0.01 b 固定碳 Fixed carbon/% 44.94±1.33 b 51.42±2.81 a 44.54±1.03 b 有机碳 Organic carbon/% 59.94±0.34 a 59.71±0.39 a 56.51±0.00 b C/N 31.38±0.05 b 36.63±0.23 a 30.57±0.19 c 同行数字后不同小写字母表示不同处理之间差异显著(P<0.05)。

Data with different lowercase letters on the same row indicate significant differences (P<0.05). -

[1] YANG J W, LIANG B, ZHANG Y M, et al. Genome-wide association study of eigenvectors provides genetic insights into selective breeding for tomato metabolites [J]. BMC Biology, 2022, 20(1): 120. DOI: 10.1186/s12915-022-01327-x

[2] 曾晓娟, 张驰, 何艳清, 等. 基于1980 - 2019年FAO数据的世界番茄生产状况分析 [J]. 湖南农业科学, 2021, (11):104−108. ZENG X J, ZHANG C, HE Y Q, et al. Analysis of world tomato production based on FAO data from 1980 to 2019 [J]. Hunan Agricultural Sciences, 2021(11): 104−108. (in Chinese)

[3] 我国西红柿行业现状栽培面积、产量及出口量呈增长态势市场走向多元化发展. 观研报告网[EB/OL]. [2022-09-29].https://www. chinabaogao. com/detail/611309. html [4] 韩雪, 常瑞雪, 杜鹏祥, 等. 不同蔬菜种类的产废比例及性状分析 [J]. 农业资源与环境学报, 2015, 32(4):377−382. HAN X, CHANG R X, DU P X, et al. Straw coefficient and properties of different vegetable wastes [J]. Journal of Agricultural Resources and Environment, 2015, 32(4): 377−382. (in Chinese)

[5] 张飞雪, 周利利, 周肖瑜, 等. 我国番茄秸秆废弃物资源化利用研究进展 [J]. 蔬菜, 2023, (2):28−32. ZHANG F X, ZHOU L L, ZHOU X Y, et al. Research progress on resource utilization of tomato straw waste in China [J]. Vegetables, 2023(2): 28−32. (in Chinese)

[6] 余亚琳, 胡静, 樊兆博, 等. 设施菜田夏季闷棚对还田秸秆矿化和CO2排放的影响 [J]. 安徽农业科学, 2020, 48(2):81−84,92. DOI: 10.3969/j.issn.0517-6611.2020.02.023 YU Y L, HU J, FAN Z B, et al. Effect of stuffy shed on mineralization and CO2 emission of returning straw in greenhouse vegetable field in summer [J]. Journal of Anhui Agricultural Sciences, 2020, 48(2): 81−84,92. (in Chinese) DOI: 10.3969/j.issn.0517-6611.2020.02.023

[7] BEESLEY L, MORENO-JIMÉNEZ E, GOMEZ-EYLES J L, et al. A review of biochars' potential role in the remediation, revegetation and restoration of contaminated soils [J]. Environmental Pollution, 2011, 159(12): 3269−3282. DOI: 10.1016/j.envpol.2011.07.023

[8] 郝树芹, 陈强, 丁超武, 等. 设施番茄秸秆还田关键技术及其在黄瓜优质高产栽培中的应用 [J]. 中国瓜菜, 2023, 36(2):112−116. DOI: 10.3969/j.issn.1673-2871.2023.02.019 HAO S Q, CHEN Q, DING C W, et al. Key techniques of tomato straw returning in greenhouse and its application in cucumber high-quality and high-yield cultivation [J]. China Cucurbits and Vegetables, 2023, 36(2): 112−116. (in Chinese) DOI: 10.3969/j.issn.1673-2871.2023.02.019

[9] 耿凤展, 李荣华, 高波, 等. 番茄秸秆高温堆肥作为番茄育苗基质的循环利用研究 [J]. 中国土壤与肥料, 2016, (1):102−106. DOI: 10.11838/sfsc.20160118 GENG F Z, LI R H, GAO B, et al. Composting of tomato residues and cow dung under the aerobic condition and its recyclable potential in tomato nursery seedling [J]. Soil and Fertilizer Sciences in China, 2016(1): 102−106. (in Chinese) DOI: 10.11838/sfsc.20160118

[10] DOMINGO J L, NADAL M. Domestic waste composting facilities: A review of human health risks [J]. Environment International, 2009, 35(2): 382−389. DOI: 10.1016/j.envint.2008.07.004

[11] 朱屹, 李俊良, 焦博, 等. 整合宏组学方法研究番茄与玉米秸秆共堆肥生境中的关键微生物及其功能 [J]. 福建农业学报, 2020, 35(7):764−772. ZHU Y, LI J L, JIAO B, et al. Functional microorganisms in tomato stalks/maize straws co-compost unveiled by integrated meta-omics [J]. Fujian Journal of Agricultural Sciences, 2020, 35(7): 764−772. (in Chinese)

[12] 时振宇, 陈健, 贾凯, 等. 番茄秸秆复合基质对温室黄瓜生长、产量及果实品质的影响 [J]. 新疆农业科学, 2020, 57(1):78−85. SHI Z Y, CHEN J, JIA K, et al. Effects of tomato straw composite substrate on growth, yield and fruit quality of cucumber in greenhouses [J]. Xinjiang Agricultural Sciences, 2020, 57(1): 78−85. (in Chinese)

[13] 陈羚, 邹永杰, 董保成. 农业设施种植废弃物厌氧集中处理适用性研究 [J]. 中国沼气, 2018, 36(6):32−35. DOI: 10.3969/j.issn.1000-1166.2018.06.006 CHEN L, ZOU Y J, DONG B C. Applicability of Anaerobic Centralized Treatment for Plant Waste form Agricultural Facility [J]. China Biogas, 2018, 36(6): 32−35. (in Chinese) DOI: 10.3969/j.issn.1000-1166.2018.06.006

[14] CLARE A, SHACKLEY S, JOSEPH S, et al. Competing uses for China’s straw: The economic and carbon abatement potential of biochar [J]. GCB Bioenergy, 2015, 7(6): 1272−1282. DOI: 10.1111/gcbb.12220

[15] 朱启林, 曹明, 张雪彬, 等. 不同热解温度下禾本科植物生物炭理化特性分析 [J]. 生物质化学工程, 2021, 55(4):21−28. DOI: 10.3969/j.issn.1673-5854.2021.04.004 ZHU Q L, CAO M, ZHANG X B, et al. Physicochemical and infrared spectroscopic properties of Gramineae plants biochar at different pyrolysis temperatures [J]. Biomass Chemical Engineering, 2021, 55(4): 21−28. (in Chinese) DOI: 10.3969/j.issn.1673-5854.2021.04.004

[16] CHANDRA S, BHATTACHARYA J. Influence of temperature and duration of pyrolysis on the property heterogeneity of rice straw biochar and optimization of pyrolysis conditions for its application in soils [J]. Journal of Cleaner Production, 2019, 215: 1123−1139. DOI: 10.1016/j.jclepro.2019.01.079

[17] CAO G L, ZHANG X Y, ZHENG F C. Inventory of black carbon and organic carbon emissions from China [J]. Atmospheric Environment, 2006, 40(34): 6516−6527. DOI: 10.1016/j.atmosenv.2006.05.070

[18] PENG X, YE L L, WANG C H, et al. Temperature- and duration-dependent rice straw-derived biochar: Characteristics and its effects on soil properties of an Ultisol in Southern China [J]. Soil and Tillage Research, 2011, 112(2): 159−166. DOI: 10.1016/j.still.2011.01.002

[19] 曹丽花, 连玉珍, 刘合满. 基于文献计量的秸秆生物炭研究进展 [J]. 安徽农业科学, 2023, 51(4):225−228,252. DOI: 10.3969/j.issn.0517-6611.2023.04.054 CAO L H, LIAN Y Z, LIU H M. Research progress of straw biochar based on bibliometrics [J]. Journal of Anhui Agricultural Sciences, 2023, 51(4): 225−228,252. (in Chinese) DOI: 10.3969/j.issn.0517-6611.2023.04.054

[20] ZHOU Y Y, BAI Z Y, YANG X Y, et al. In-situ grown NiCo bimetal anchored on porous straw-derived biochar composites with boosted microwave absorption properties [J]. International Journal of Minerals, Metallurgy and Materials, 2023, 30(3): 515−524. DOI: 10.1007/s12613-022-2496-2

[21] KAUR P, SHARMA N, KAUR K. Influence of pyrolysis temperature on rice straw biochar properties and corresponding effects on dynamic changes in bispyribac-sodium adsorption and leaching behavior in soil [J]. Pedosphere, 2023, 33(3): 463−478. DOI: 10.1016/j.pedsph.2022.06.046

[22] YUAN R, SI T R, LU Q Q, et al. Rape straw biochar enhanced Cd immobilization in flooded paddy soil by promoting Fe and sulfur transformation [J]. Chemosphere, 2023, 339: 139652. DOI: 10.1016/j.chemosphere.2023.139652

[23] 徐洋, 任奕林, 王浩杰, 等. 不同制备条件下油菜秸秆生物炭用作缓释载体的综合评价 [J]. 浙江农业学报, 2023, 35(4):893−902. DOI: 10.3969/j.issn.1004-1524.2023.04.16 XU Y, REN Y L, WANG H J, et al. Comprehensive evaluation of rape straw biochar as slow-release carrier under different preparation conditions [J]. Acta Agriculturae Zhejiangensis, 2023, 35(4): 893−902. (in Chinese) DOI: 10.3969/j.issn.1004-1524.2023.04.16

[24] ZHAO X C, OUYANG W, HAO F H, et al. Properties comparison of biochars from corn straw with different pretreatment and sorption behaviour of atrazine [J]. Bioresource Technology, 2013, 147: 338−344. DOI: 10.1016/j.biortech.2013.08.042

[25] 黄华, 王雅雄, 唐景春, 等. 不同烧制温度下玉米秸秆生物炭的性质及对萘的吸附性能 [J]. 环境科学, 2014, 35(5):1884−1890. HUANG H, WANG Y X, TANG J C, et al. Properties of maize stalk biochar produced under different pyrolysis temperatures and its sorption capability to naphthalene [J]. Environmental Science, 2014, 35(5): 1884−1890. (in Chinese)

[26] 张璐, 贾丽, 陆文龙, 等. 不同碳化温度下玉米秸秆生物炭的结构性质及其对氮磷的吸附特性 [J]. 吉林大学学报(理学版), 2015, 53(4):802−808. ZHANG L, JIA L, LU W L, et al. Structural properties of corn straw biochar and characteristics of its adsorption for nitrogen and phosphate at different carbonization temperature [J]. Journal of Jilin University (Science Edition), 2015, 53(4): 802−808. (in Chinese)

[27] TAN G Q, LIU Y, XIAO D. Influence of different pyrolysis methods on the sorption property of rice straw biochar [J]. Separation Science and Technology, 2019, 54(17): 2773−2782. DOI: 10.1080/01496395.2018.1553981

[28] 张春燕. 植物生物炭制备、性能及其对作物生长影响研究[D]. 南京: 南京农业大学, 2018. ZHANG C Y. Study on biochar preparation based from plant-type and its effect on crop growth[D]. Nanjing: Nanjing Agricultural University, 2018. (in Chinese)

[29] 孙玲, 贾明云, 刘壮壮, 等. 不同热解温度和升温速率下杨树枝条生物质炭产率和理化性质分析 [J]. 植物资源与环境学报, 2023, 32(3):71−82,91. DOI: 10.3969/j.issn.1674-7895.2023.03.08 SUN L, JIA M Y, LIU Z Z, et al. Analyses on yield and physicochemical properties of poplar branch biochars at different pyrolysis temperatures and heating rates [J]. Journal of Plant Resources and Environment, 2023, 32(3): 71−82,91. (in Chinese) DOI: 10.3969/j.issn.1674-7895.2023.03.08

[30] 中华人民共和国农业农村部. 生物炭检测方法通则: NY/T 3672—2020[S]. 北京: 中国农业出版社, 2020. [31] 鲁如坤. 土壤农业化学分析方法[M]. 北京: 中国农业科技出版社, 2000: 147-149. [32] 翁诗甫, 徐怡庄. 傅里叶变换红外光谱分析[M]. 3版. 北京: 化学工业出版社, 2016. [33] 王德胜, 何振, 冯勇, 等. 南疆棉秆生物炭的制备及理化特性分析 [J]. 塔里木大学学报, 2018, 30(1):124−131. DOI: 10.3969/j.issn.1009-0568.2018.01.016 WANG D S, HE Z, FENG Y, et al. The preparation and physicochemical properties of cotton stalk biochar has been studied in southern Xinjiang [J]. Journal of Tarim University, 2018, 30(1): 124−131. (in Chinese) DOI: 10.3969/j.issn.1009-0568.2018.01.016

[34] 陈心想, 耿增超. 生物质炭在农业上的应用 [J]. 西北农林科技大学学报(自然科学版), 2013, 41(2):167−174. CHEN X X, GENG Z C. Application of biochar in agriculture [J]. Journal of Northwest A & F University (Natural Science Edition), 2013, 41(2): 167−174. (in Chinese)

[35] 徐亮, 王豹祥, 汪健, 等. 不同热解温度制备的水稻秸秆生物炭理化特性分析 [J]. 土壤通报, 2020, 51(1):136−143. XU L, WANG B X, WANG J, et al. Physical and chemical properties of carbonized rice-straw prepared at different temperatures [J]. Chinese Journal of Soil Science, 2020, 51(1): 136−143. (in Chinese)

[36] DEMIRBAS A. Effects of temperature and particle size on bio-char yield from pyrolysis of agricultural residues [J]. Journal of Analytical and Applied Pyrolysis, 2004, 72(2): 243−248. DOI: 10.1016/j.jaap.2004.07.003

[37] JOHANNES L, STEPHEN J. Biochar for environmental management: An introduction[J]. Biochar for environmental management Science & Technology, 2009, 25, 15801-15811.

[38] 闫郑方, 张嵚, 余鑫, 等. 秸秆生物炭的特性及其在重金属污染农田中的应用 [J]. 湖南师范大学自然科学学报, 2023, 46(1):38−47. YAN Z F, ZHANG Q, YU X, et al. Characteristics of straw biochar and its application in heavy metal-contaminated farmland [J]. Journal of Natural Science of Hunan Normal University, 2023, 46(1): 38−47. (in Chinese)

[39] 黄康. 不同热解温度秸秆生物炭还田培肥土壤及其固碳潜力的研究[D]. 武汉: 华中农业大学, 2022 HUANG K. Study on soil fertilization and carbon sequestration potential of different pyrolysis temperature biochar returning[D]. Wuhan: Huazhong Agricultural University, 2022. (in Chinese)

[40] 吴行, 王秀斌, 郑琴, 等. 水滑石改性生物炭有效提高设施菜田土壤磷的吸附性能 [J]. 植物营养与肥料学报, 2022, 28(9):1652−1663. DOI: 10.11674/zwyf.2021687 WU H, WANG X B, ZHENG Q, et al. Hydrotalcite-modified biochar effectively improves phosphorus adsorption capacity in greenhouse vegetable soil [J]. Journal of Plant Nutrition and Fertilizers, 2022, 28(9): 1652−1663. (in Chinese) DOI: 10.11674/zwyf.2021687

[41] 冯诗慧, 孙正一, 张金硕, 等. 热解温度对生物炭循环伏安曲线特性的影响 [J]. 环境化学, 2021, 40(3):828−833. DOI: 10.7524/j.issn.0254-6108.2020021902 FENG S H, SUN Z Y, ZHANG J S, et al. Effect of carbonization temperature on the cycle voltammetry characteristics of biochar [J]. Environmental Chemistry, 2021, 40(3): 828−833. (in Chinese) DOI: 10.7524/j.issn.0254-6108.2020021902

[42] 刘铭轩. 活性炭研究进展及展望 [J]. 内蒙古石油化工, 2017, 43(3):35−36. DOI: 10.3969/j.issn.1006-7981.2017.03.012 LIU M X. Research progress and prospect of activated carbon [J]. Inner Mongolia Petrochemical Industry, 2017, 43(3): 35−36. (in Chinese) DOI: 10.3969/j.issn.1006-7981.2017.03.012

[43] 张伟明, 修立群, 吴迪, 等. 生物炭的结构及其理化特性研究回顾与展望 [J]. 作物学报, 2021, 47(1):1−18. DOI: 10.3724/SP.J.1006.2021.02021 ZHANG W M, XIU L Q, WU D, et al. Review of biochar structure and physicochemical properties [J]. Acta Agronomica Sinica, 2021, 47(1): 1−18. (in Chinese) DOI: 10.3724/SP.J.1006.2021.02021

[44] 张昌天, 郭建华, 王龙, 等. 生物炭裂解温度和施用水平对土壤导水率的影响 [J]. 江苏农业科学, 2020, 48(6):209−214. ZHANG C T, GUO J H, WANG L, et al. Influences of biochar pyrolysis temperature and application level on soil hydraulic conductivity [J]. Jiangsu Agricultural Sciences, 2020, 48(6): 209−214. (in Chinese)

[45] CHEN W F, MENG J, HAN X R, et al. Past, present, and future of biochar [J]. Biochar, 2019, 1(1): 75−87. DOI: 10.1007/s42773-019-00008-3

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载: