Response Surface Optimization of Medium Formulation for Culture of Lyophyllum decastes

-

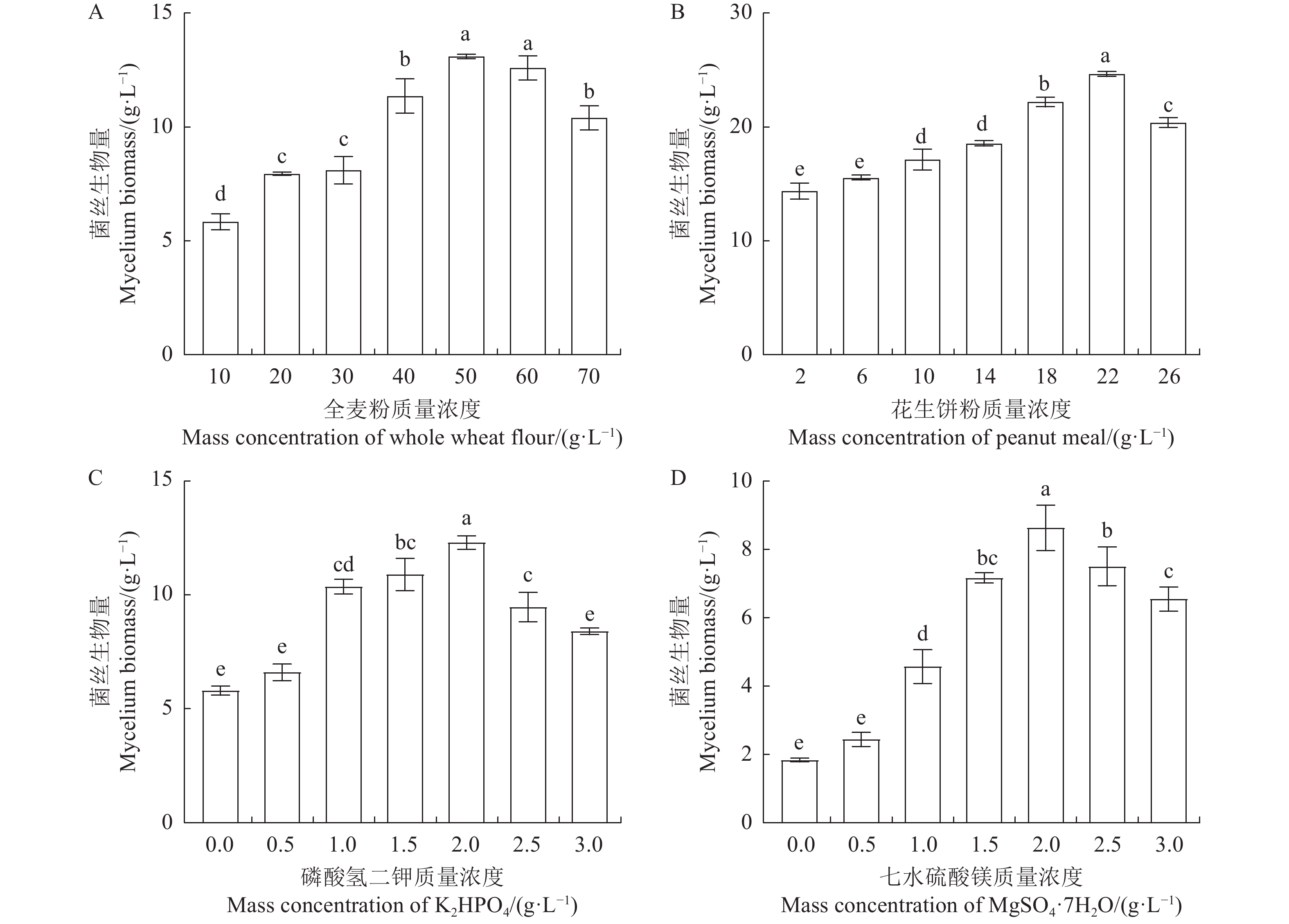

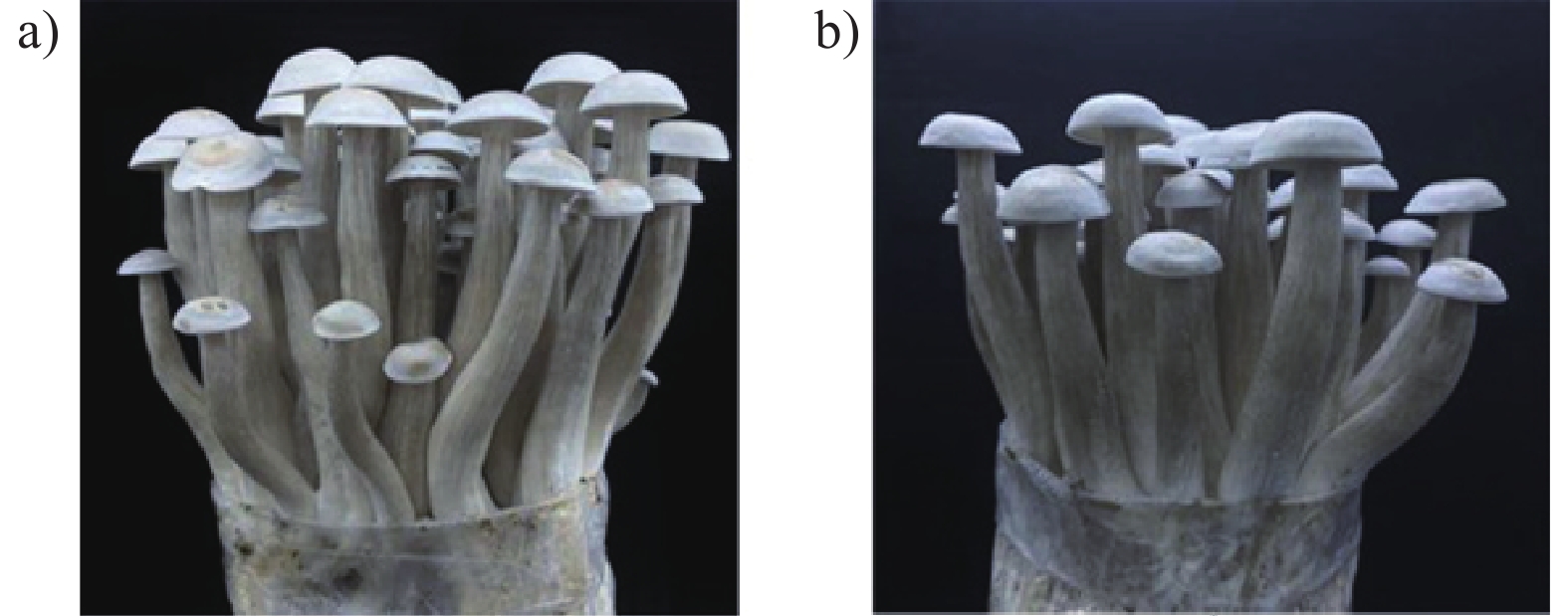

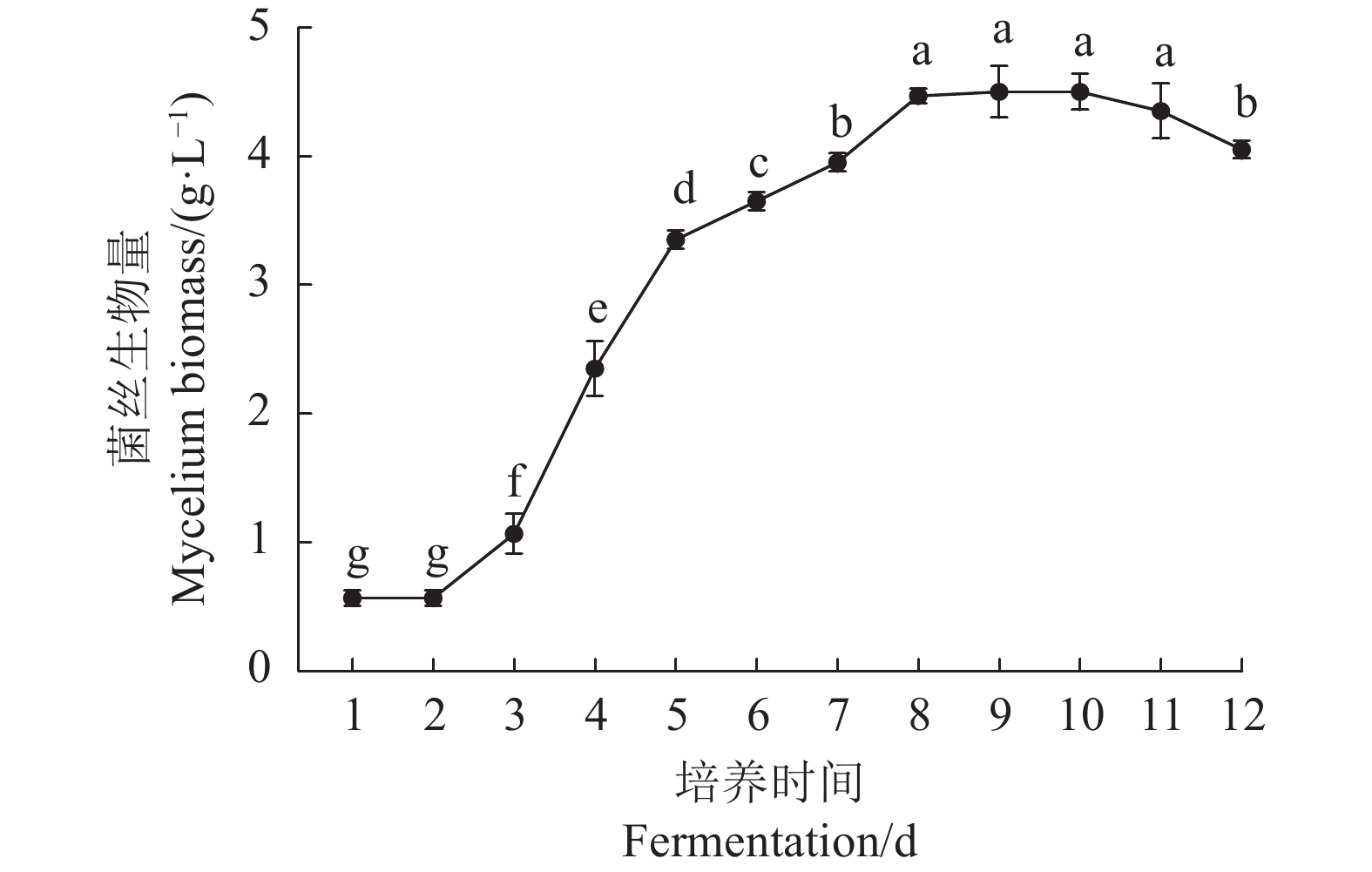

摘要:目的 以提高鹿茸菇液体菌种菌丝生物量为目的,通过优化液体菌种发酵配方,制备优良液体菌种,推动鹿茸菇工厂化生产快速发展。方法 以鹿茸菇为研究材料,采用摇瓶培养方式,通过单因素设计分析6种碳源、8种氮源、10种金属离子对鹿茸菇菌丝生长的影响。采用Box-Behnken响应面法进一步优化单因素筛选出的碳源、氮源与金属离子,比较分析液体菌种与固体菌种应用于鹿茸菇生产的优劣性。结果 适合鹿茸菇生长的营养要素分别为全麦粉、花生饼粉、KH2PO4与MgSO4·7H2O,营养要素间的最优配方为全麦粉47 g·L−1、花生饼粉22 g·L−1、KH2PO4 2.00 g·L−1、MgSO4·7H2O 2.00 g·L−1,当发酵培养至第8 d时,菌丝生物量达到最大值(32.81±1.10 g·L−1),以优化配方制备的鹿茸菇液体菌种菌丝生物量较初始配方提高了7.34倍。在生产试验中液体菌种较固体菌种,制种时间缩短48 d,菌丝萌发时间缩短2 d,单袋产量提高15.47%。结论 本研究研发的液体菌种发酵配方可获得高质量的生产用种,以液体发酵方式制备鹿茸菇生产用种适合鹿茸菇工厂化生产。Abstract:Objective To improve the mycelium biomass of Lyophyllum decast liquid seeds, high-quality liquid seeds are prepared by optimizing the liquid fermentation formula, to promote the rapid development of industrial production of L. decastes mushrooms.Methods Taking L. decastes as the research material, the effects of 6 kinds of carbon sources, 8 kinds of nitrogen sources, and 10 kinds of metal ions on the mycelium growth were analyzed by single-factor design. The carbon source, nitrogen source, and metal ions screened out by single-factor design were further optimized by the Box-Behnken response surface method, and the advantages and disadvantages of liquid seeds and solid seeds in the production of L. decastes mushrooms were compared.Results The nutritional elements suitable for the growth of L. decastes were whole wheat flour, peanut meal, K2HPO4, and MgSO4·7H2O, and the optimal formula was whole wheat flour 47 g·L−1, peanut meal 22 g·L−1, K2HPO4 2.00 g·L−1, MgSO4·7H2O 2.00 g·L−1. When the fermentation culture reached the 8th day, the dry cell mass (DCM) was 32.81±1.10 g·L−1. Compared with the DCM by the initial formula, the DCM prepared with the optimized formula was increased by 7.34 times. Compared with solid seeds, the production time of liquid seeds was shortened by 48 days, the time of mycelium germination was shortened by 2 days, and the yield per bag increased by 15.47%, in industrial production.Conclusion The liquid fermentation formula developed in this study can obtain high-quality production seeds, and the liquid fermentation strategy for the preparation of seeds is suitable for the industrial production of L. decastes mushrooms.

-

Keywords:

- Lyophyllum decastes /

- Liquid seeds /

- Liquid fermentation formula /

- Mycelium biomass

-

-

表 1 Box-Behnken设计因素水平及编码

Table 1 Codes and levels of factors in Box-Behnken experiment

水平

Level因素 Factors/(g·L−1) A 全麦粉

Whole wheat flourB 花生饼粉

Peanut mealC 磷酸氢二钾

K2HPO4/D七水硫酸镁

MgSO4·7H2O/+1 55 24 2.25 2.25 0 50 22 2.00 2.00 −1 45 20 1.75 1.75 表 2 Box-Behnken试验设计及试验结果

Table 2 Design and results of Box-Behnken experiment

试验号

NumberA全麦粉

Whole wheat

flourB花生饼粉

Peanut

mealC磷酸氢

二钾

K2HPO4D七水

硫酸镁

MgSO4·7H2O菌丝生物量

Mycelium

biomass/

(g·L−1)1 −1 −1 0 0 29.61±1.18 2 +1 −1 0 0 29.90±1.45 3 −1 +1 0 0 32.27±1.11 4 +1 +1 0 0 28.77±2.01 5 0 0 −1 −1 30.79±1.28 6 0 0 +1 −1 29.41±1.88 7 0 0 −1 +1 28.00±0.30 8 0 0 +1 +1 30.21±1.09 9 −1 0 0 −1 31.72±2.12 10 +1 0 0 −1 29.37±1.63 11 −1 0 0 +1 30.20±2.00 12 +1 0 0 +1 29.11±2.51 13 0 −1 −1 0 29.29±4.29 14 0 +1 −1 0 30.00±0.68 15 0 −1 +1 0 30.20±1.45 16 0 +1 +1 0 30.11±4.80 17 −1 0 −1 0 30.00±2.97 18 +1 0 −1 0 30.17±4.12 19 −1 0 +1 0 32.48±0.21 20 +1 0 +1 0 28.73±4.01 21 0 −1 0 −1 30.09±4.38 表 3 二次回归方程方差分析

Table 3 ANOVA on quadratic regression equation

来源

Source平方和

SS自由度

DS均方

MSF P 显著性

Significance模型

Model0.7362 14 0.0526 98.95 <0.0001 ** A 0.0878 1 0.0878 165.28 <0.0001 ** B 0.0127 1 0.0127 23.85 0.0002 ** C 0.0074 1 0.0074 13.96 0.0022 ** D 0.0248 1 0.0248 0.31 <0.0001 ** AB 0.0358 1 0.0358 0.02 <0.0001 ** AC 0.0371 01 0.0371 6.12 <0.0001 * AD 0.0044 1 0.0044 0.32 0.0118 * BC 0.0015 1 0.0015 0.08 0.1114 BD 0.0011 1 0.0011 0.02 0.1702 CD 0.0327 1 0.0327 0.03 <0.0001 ** A2 0.1299 1 0.1299 169.26 <0.0001 ** B2 0.1974 1 0.1974 9.19 <0.0001 ** C2 0.2045 1 0.2045 127.92 <0.0001 ** D2 0.2302 1 0.2302 37.54 <0.0001 ** 残差

Residual0.0074 14 0.0005 失拟项

Lack of fit0.0047 10 0.0005 0.69 0.7126 纯误差

Pure error0.0027 4 0.0007 总和

Cor total0.7436 28 R2=0.9900 R2adj=0.9800 *表示差异显著(P<0.05),**表示差异极显著(P<0.01)。

* indicates significant difference at P<0.05; ** extremely significant at P<0.01.表 4 液体菌种和固体菌种栽培过程及出菇比较

Table 4 Comparison of fermentation processes andmushroom fruiting using liquid and solid media

指标

Index液体菌种

Liquid strain固体菌种

Solid strain原种培养时间 Original culture time/d 8 24 栽培种培养时间 Culture spawn incubation time/d 8 40 制种周期 Seed production cycle/d 16 64 菌丝萌发时间 Time of mycelium germination/d 2 4 满袋时间 Bags full time/d 42 45 污染率 Pollution rate/% 8.33 29.17 现蕾时间 Budding time/d 7 9 采收时间 Harvest time/d 25 27 单包产量 Single package output/g 500.89±20.12 432.00±25.36 子实体整齐度 Fruiting body uniformity +++ ++ 菇长 Length/cm 12.82±1.19 11.76±0.83 菇径 Size/mm 12.37±1.66 17.36±1.71 盖高 Height/mm 6.86±1.35 10.72±1.85 盖径 Diameter/mm 20.06±3.77 26.10±3.94 +++表示子实体整齐度较一致; ++表示子实体整齐度一致。

+++shows uniform fruiting body formation; ++acceptable fruiting body uniformity. -

[1] 戴玉成, 周丽伟, 杨祝良, 等. 中国食用菌名录 [J]. 菌物学报, 2010, 29(1):1−21. DAI Y C, ZHOU L W, YANG Z L, et al. A revised checklist of edible fungi in China [J]. Mycosystema, 2010, 29(1): 1−21.(in Chinese)

[2] 程继红. 鹿茸菇的栽培现状与营养保健价值 [J]. 食药用菌, 2021, 29(1):12−15. CHENG J H. Cultivation status and its nutrition and health care value of Lyophyllum decastes [J]. Edible and Medicinal Mushrooms, 2021, 29(1): 12−15.(in Chinese)

[3] 程继红, 郑慧芬, 贲伟东, 等. 荷叶离褶伞工厂化栽培 [J]. 食用菌学报, 2008, 15(2):20−22. CHENG J H, ZHENG H F, BEN W D, et al. Industrial cultivation of Lyophyllum decastes [J]. Acta Edulis Fungi, 2008, 15(2): 20−22.(in Chinese)

[4] 木村荣一, 王建兵. 鹿茸菇的工厂化栽培 [J]. 食药用菌, 2019, 27(4):237−240. Eiichi K, WANG J B. Industrial cultivation of Lyophyllum decastes [J]. Edible and Medicinal Mushrooms, 2019, 27(4): 237−240.(in Chinese)

[5] 管婉, 陈业桥, 唐利华, 等. 食用菌液体菌种的制备及应用研究概况 [J]. 食用菌, 2021, 43(5):5−7. GUAN W, CHEN Y Q, TANG L H, et al. General situation of preparation and application of liquid strains of edible fungi [J]. Edible Fungi, 2021, 43(5): 5−7.(in Chinese)

[6] 徐来清, 张书祥. 假蜜环菌发酵工艺的优化研究 [J]. 生物学杂志, 2014, 31(3):91−94. XU L Q, ZHANG S X. The optimization of the fermentation technology of Armillariella tabescens [J]. Journal of Biology, 2014, 31(3): 91−94.(in Chinese)

[7] 刘敏, 卢红, 黄媛媛, 等. 茶树菇液体发酵条件研究 [J]. 北方园艺, 2016(11):142−144. LIU M, LU H, HUANG Y Y, et al. Study on the liquid fermentation condition of agrocybeaegerita(brig. ) sing [J]. Northern Horticulture, 2016(11): 142−144.(in Chinese)

[8] FENG Y L, LI W Q, WU X Q, et al. Statistical optimization of media for mycelial growth and exo-polysaccharide production by Lentinus edodes and a kinetic model study of two growth morphologies [J]. Biochemical Engineering Journal, 2010, 49(1): 104−112. DOI: 10.1016/j.bej.2009.12.002

[9] 杨丽维, 王玉, 班立桐, 等. 杏鲍菇液体菌种培养基的筛选和优化 [J]. 北方园艺, 2014(6):150−152. YANG L W, WANG Y, BAN L T, et al. Study on the screening and optimizing of liquid spawn medium of Pleurotus eryngii [J]. Northern Horticulture, 2014(6): 150−152.(in Chinese)

[10] BOX G E P. Statistics for Experiments: An Introduction to Design, Data Analysis and Model Building [M]. New York: Wiley, 1990.

[11] HUMFELD H. The production of mushroom Mycelium (Agaricus campestris) in submerged culture [J]. Science, 1948, 107(2780): 373. DOI: 10.1126/science.107.2780.373

[12] 刘启燕, 戚俊, 周洪英, 等. 食用菌液体菌种工厂化生产应用现状及发展浅析 [J]. 食用菌, 2018, 40(6):8−10, 22. DOI: 10.3969/j.issn.1000-8357.2018.06.003 LIU Q Y, QI J, ZHOU H Y, et al. Present situation and development tendency of using liquid spawn of edible mushrooms in industrialized production [J]. Edible Fungi, 2018, 40(6): 8−10, 22.(in Chinese) DOI: 10.3969/j.issn.1000-8357.2018.06.003

[13] 李立功. 荷叶离褶伞研究进展 [J]. 中国林副特产, 2019(1):79−81, 90. LI L G. Research progress of Lyophyllum decastes [J]. Forest by-Product and Speciality in China, 2019(1): 79−81, 90.(in Chinese)

[14] 魏生龙, 王治江, 于海萍, 等. 荷叶离褶伞生物学特性研究 [J]. 菌物学报, 2006, 25(1):101−108. WEI S L, WANG Z J, YU H P, et al. Biological characteristics of Lyophyllum decastes (Fr. : Fr. ) singer [J]. Mycosystema, 2006, 25(1): 101−108.(in Chinese)

[15] 魏生龙, 连海丽, 于海萍, 等. 矿质营养与其他生长物质对荷叶离褶伞菌丝生长的影响 [J]. 菌物学报, 2008, 27(2):201−208. WEI S L, LIAN H L, YU H P, et al. The influence of mineral nutritions and other growth substances on the growth of mycelia of Lyophyllum decastes [J]. Mycosystema, 2008, 27(2): 201−208.(in Chinese)

[16] 张凌姗. 鹿茸菇生态学特性与液体菌种配方的优化研究 [J]. 食药用菌, 2020, 28(6):425−427,439. ZHANG L S. Study on ecological characteristics and optimization of liquid spawn formula of Lyophyllum decastes [J]. Edible and Medicinal Mushrooms, 2020, 28(6): 425−427,439.(in Chinese)

[17] 张汉燚, 王治江, 席亚丽, 等. 荷叶离褶伞中试发酵条件与培养基优化研究 [J]. 中国酿造, 2012, 31(1):96−99. ZHANG H Y, WANG Z J, XI Y L, et al. Optimization of fermentation conditions and medium components for pilot production of Lyophyllum decastes [J]. China Brewing, 2012, 31(1): 96−99.(in Chinese)

[18] 席亚丽, 王治江, 魏生龙, 等. 荷叶离褶伞摇瓶发酵条件研究 [J]. 河西学院学报, 2011, 27(2):68−74,57. XI Y L, WANG Z J, WEI S L, et al. Study on fermentation conditions of Lyophyllum decastes in shake flask [J]. Journal of Hexi University, 2011, 27(2): 68−74,57.(in Chinese)

[19] 徐长毫, 董冰雪, 李长杰, 等. 响应面法优化灵芝AM21菌株液体深层发酵培养基配方 [J]. 食用菌学报, 2011, 18(4):31−36. XU C H, DONG B X, LI C J, et al. Optimization of fermentation medium for triterpenoid production by Ganoderma lucidum AM21 using response surface methodology [J]. Acta Edulis Fungi, 2011, 18(4): 31−36.(in Chinese)

[20] 李莉, 张赛, 何强, 等. 响应面法在试验设计与优化中的应用 [J]. 实验室研究与探索, 2015, 34(8):41−45. LI L, ZHANG S, HE Q, et al. Application of response surface methodology in experiment design and optimization [J]. Research and Exploration in Laboratory, 2015, 34(8): 41−45.(in Chinese)

[21] 程继红. 名贵食药用菌鹿茸菇商业化生产现状与发展前景 [J]. 食药用菌, 2014, 22(4):194−197. CHENG J H. The commercial production situation and prospects of the new valuable edible and medicinal mushroom, Lyophyllum decastes [J]. Edible and Medicinal Mushrooms, 2014, 22(4): 194−197.(in Chinese)

下载:

下载: